Three Deformation Processes of Hot-rolled Seamless Steel Pipes

How to produce hot-rolled seamless steel pipe?

The production process of hot-rolled seamless steel pipe includes several basic processes such as blank preparation before rolling, pipe heating, piercing, rolling, sizing and reducing, pipe cooling and finishing.

There are three main deformation processes in the production of hot-rolled seamless steel pipes: piercing, rolling and sizing/reducing. Their respective technical purposes and requirements are:

1. Perforation

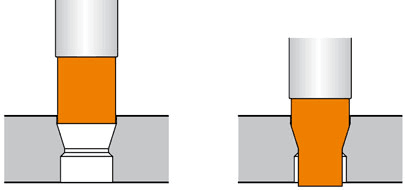

Changing the solid tube blank into a hollow capillary tube; we can understand it as shaping, that is, setting the cross section of the rolled piece into a ring. This equipment is called a punching machine.

2. Tube rolling

The requirements for the rolling process are: first, when the thick-walled capillary is changed to thin-walled scrap steel pipe (reducing the wall length), it is necessary to ensure the high uniformity of the wall thickness of the steel pipe; secondly, the steel pipe has good internal and external surface quality.

3. Sizing/reducing (including stretching)

The big circle becomes small, and the corresponding equipment is a sizing (reducing) machine. Its main function is to eliminate the difference in the outer diameter of the steel pipe (same piece or batch) caused by the rolling process of the previous process, so as to improve the quality of the hot-rolled finished pipe. Outer diameter accuracy and roundness. Diameter reduction is to reduce the large pipe diameter to the required specification size and accuracy. Tension reduction is to reduce the diameter under the action of the tension of the front and rear racks, and at the same time reduce the wall. The equipment used for sizing and reducing is sizing (reducing) sizing machine.

The requirements for the sizing and reducing process are: firstly, under the conditions of a certain total reducing rate and a small single frame reducing rate, the purpose of sizing is achieved; secondly, it is possible to produce a variety of tube blanks with one specification. The task of standardizing the finished pipe; third, the outer surface quality of the steel pipe can be further improved.

The tension reducing machine (SRM) is the last process in the production of hot-rolled seamless steel pipes. It can produce finished products of various specifications from a few blanks. Steel pipe manufacturers at home and abroad have widely used tension reducing technology. The process principle takes three-roller diameter reduction as an example, generally without a mandrel, by controlling the tension formed by the speed difference between the racks, the steel pipe is reduced in diameter and wall in a series of passes.

Diameter reduction: Diameter reduction forming is a pressure forging process. During the forming process, the workpiece completely or partially passes through the hole of the abrasive tool (drawing punch) under pressure to reduce the cross section. The tapering of the solid body results in a reduction in cross-section, in contrast to the necking of the hollow body.

As a carbon steel pipe manufacturer, Permanent Steel Manufacturing Co.,Ltd specializes in the production and supply of seamless steel pipes: thin-wall/thick-wall seamless pipes, precision seamless pipes, small-diameter seamless pipes, providing various specifications and materials, large inventory, rich experience, and can be provided customized service according to customer requirements.

- 【Prev】 : How to Cut Carbon Steel Pipe?

- 【Next】 : ASTM A36 American Standard Carbon Steel