Seamless Tube Eddy Current Flaw Detection

According to the shape of the detection coil, it can be divided into three types: through type (for wire, rod and pipe detection), probe type (for partial detection of component surface) and insertion type (for internal detection of pipe holes) kind.

The advantages of eddy current flaw detection for seamless tubes are: the flaw detection results can be directly output by electrical signals, which is convenient for automatic detection; due to the non-contact method, the flaw detection speed is very fast; it is suitable for flaw detection of surface defects. The disadvantages are: the defects in the deeper parts under the surface of the seamless tube cannot be detected; it is easy to generate messy signals; it is difficult to directly distinguish the type of defects from the displayed signals obtained through detection.

The seamless tube flaw detection operation includes several steps such as surface cleaning of the test piece, stability of the flaw detector, selection of flaw detection specifications, and flaw detection test.

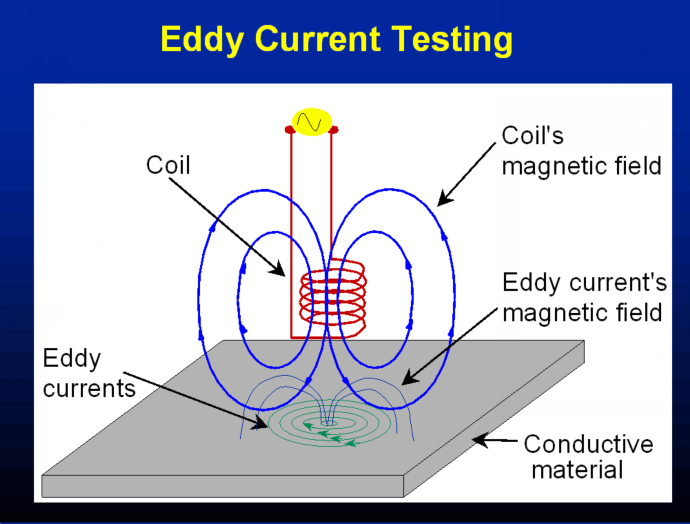

The direction of the eddy current in the seamless tube specimen is opposite to the current direction of the primary coil (or excitation coil). The alternating magnetic field generated by the eddy current changes with time, and when it passes through the primary coil, it induces alternating current in the coil. Because the direction of this current is opposite to that of the eddy current, the result is the same direction as the original exciting current in the primary coil. This means that the current in the primary coil increases due to the reaction of the eddy currents. If the eddy current changes, this increased portion also changes. On the contrary, by measuring the current change, the change of the eddy current can be measured, so as to obtain information about the defects of the seamless tube.

In addition, alternating current changes the direction of the current at a certain frequency over time. There is a certain difference in the phase of the excitation current and the reaction current, and this phase difference changes with the shape of the test piece, so this phase change can also be used as a piece of information to detect the state of the seamless steel tube test piece. Therefore, when the test piece or coil is moved at a certain speed, the type, shape and size of steel pipe defects can be known according to the waveform of the eddy current change. The alternating current generated by the oscillator is passed into the coil, and the alternating magnetic field is applied to the test piece. The eddy current of the test piece is detected by the coil and sent to the bridge circuit as an AC output.

Go here if you are looking for " Analysis and Comparison of Eddy Current Testing and Magnetic Flux Leakage Testing of Seamless Tube"