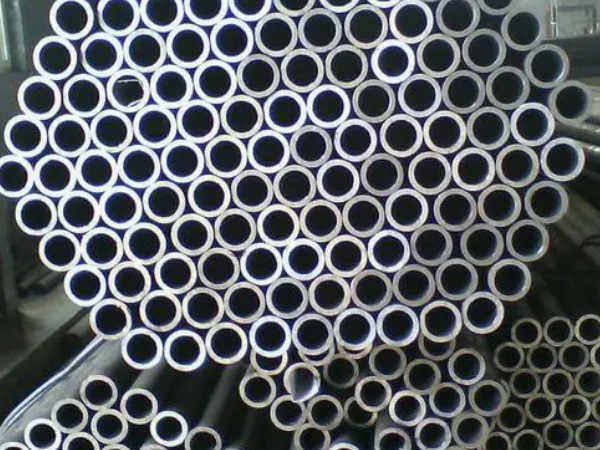

Seamless Steel Pipe Raw Material Selection and Production Process

In the production process of seamless steel pipes (SMLS), the selection and pretreatment of raw materials are crucial links. Only by selecting high-quality raw materials and undergoing reasonable pre-treatment can the quality and performance of the final product be guaranteed.

1. Raw material selection: When making seamless steel pipes, commonly used raw materials include carbon steel, alloy steel, stainless steel, etc. These raw materials have different chemical compositions and mechanical properties, and have different applications in different situations. Therefore, when selecting raw materials, it is necessary to determine the most suitable material based on actual needs and use environment.

2. Pre-processing process: Before raw materials enter the production line, a series of pre-processing procedures are required to ensure smooth subsequent processing. The first step is to inspect the raw materials, including chemical composition testing, appearance quality inspection, etc., to ensure that they meet production requirements. Next, the raw materials are cleaned, degreased and other surface treatments are carried out to remove surface dirt and oxides to ensure surface smoothness during the next step of processing. Finally, the raw materials need to be heated to reach the appropriate processing temperature.

Importance:

Raw material selection and pretreatment process directly affect the quality and performance of seamless steel pipes. High-quality raw materials can ensure that the product has good mechanical properties and corrosion resistance, thereby extending its service life. Reasonable pretreatment procedures can ensure the surface finish and dimensional accuracy of the product, making it more in line with customer requirements.

Introduction to the production process of seamless steel pipes:

1. Raw material preparation

The production process of seamless steel pipes first requires the preparation of raw materials, which mainly include steel billets and alloy elements. Steel billet is made of high-quality iron ore through high-temperature smelting, rolling and drawing processes, and has good plasticity and plasticity. Alloying elements can be added according to different needs, such as carbon, chromium, nickel, etc., to improve the strength and corrosion resistance of seamless steel pipes.

2. Heating and perforation

When making seamless steel pipes, the steel billet first needs to be heated to a certain temperature to ensure that it has sufficient plasticity. Then, in the heated state, the steel billet is put into the punching machine for piercing, and the billet is continuously cut and extruded by the rotating tool to form a hollow cylindrical shape.

3. Rolling

The perforated hollow cylindrical billet enters the rolling mill for rolling. In this step, the steel billet will be continuously deformed and compressed by multiple rollers, and finally become a seamless tube with the required diameter and thickness.

4. Pulling

After rolling, the seamless pipe needs further processing to improve its surface finish and dimensional accuracy. This step is called drawing, which mainly involves continuously stretching and shrinking the pipe to make its outer diameter and wall thickness meet the standard requirements.

5. Heat treatment

The final step in making seamless steel pipes is heat treatment. Seamless pipes are annealed, normalized or quenched at high temperatures to change their structure and properties. This step can improve the strength, hardness and corrosion resistance of seamless steel pipes to meet the needs of different use environments.

The manufacturing process of seamless pipes includes raw material preparation, heating and perforation, rolling, drawing and heat treatment. Every link is very important, and problems in any link may affect the quality of the final product. Therefore, it is necessary to strictly control the operation of each link during the production process and conduct quality inspections to ensure the final production of high-quality seamless steel pipe products. At the same time, seamless steel pipes have extensive application value in the industrial field and are of great significance in building national infrastructure and promoting economic development. Therefore, mastering the production process of seamless steel pipes can not only improve product quality, but also help promote the development of related industries.

Testing and quality control measures:

In the production process of seamless steel pipes, inspection and quality control measures are crucial links. After all, only through strict testing and quality control can the quality of seamless steel pipes be guaranteed to meet customer needs.

First, let’s take a look at the inspection process of seamless steel pipes. During the production process, seamless steel pipes need to go through multiple processes, such as hot rolling, cold drawing, pickling, etc. Each process will have an impact on the quality of the steel pipe, so corresponding testing is required. For example, in the hot rolling process, flaw detection instruments are needed to detect whether there are cracks on the surface of the steel pipe; in the cold drawing process, a metallographic microscope is needed to observe whether the internal structure of the steel pipe is uniform and dense. Only through strict testing and timely discovery and solution of problems can the quality of the final product be guaranteed.

Secondly, the quality control of seamless steel pipes is also an indispensable part. In order to ensure that products meet standard requirements, factories will establish a complete quality control system and take various measures to supervise and manage the production process. For example, formulate strict production processes and stipulate operating standards for each process; set up quality inspection points to randomly inspect each batch of products; establish quality files to record the production process and test results of each product, etc. These measures are designed to ensure the stable and reliable quality of seamless steel pipes so that customers can use them with confidence.

In addition, the quality control of seamless steel pipes also involves the selection and processing of raw materials. High-quality raw materials are the basis for ensuring product quality. Therefore, the factory will strictly control the procurement of raw materials and test their chemical composition and mechanical properties. At the same time, various parameters such as temperature, pressure, etc. need to be strictly controlled during the processing to ensure that the product meets the design requirements.

Read more: How to Choose a Suitable Seamless Steel Pipe Material?