Seamless Pipe Uses and Regulations in Chemical Processing Facilities

Date:2024-01-26 keywords: seamless pipe use, chemical processing facilities, seamless steel pipe in chemical industry

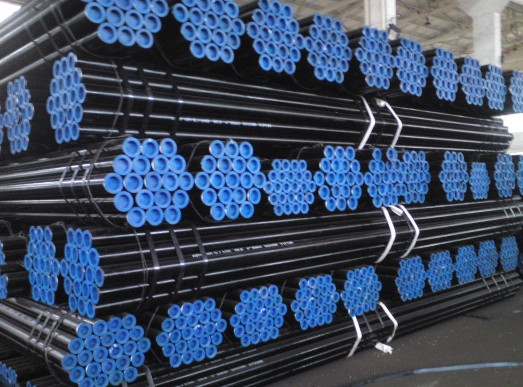

Seamless steel pipe (SMLS pipe) is a pipe material commonly used in chemical processing facilities and has many important uses and regulations. It is widely used in chemical industry, petrochemical industry, medicine, food processing and other fields. Seamless pipes are characterized by smooth internal and external surfaces without obvious welding marks, so they can meet the high requirements of chemical processing facilities on the inner walls of pipes.

The main uses of seamless pipe in chemical processing facilities include the following:

1. Transport chemical fluids

Seamless pipes can withstand extreme conditions such as high temperature and high pressure, so they are suitable for transporting various chemical fluids, such as acids, alkalis, solvents, etc. At the same time, because its inner wall is smooth, it is not easy for substances to adhere, ensuring the purity of the fluid.

2. Cooling and heating media

Seamless pipes are often used as conductive conduits for cooling and heating media in chemical processing facilities. Its high thermal conductivity and high temperature resistance allow it to effectively transfer heat and meet the facility's temperature control requirements.

3. Storing and transporting gases

To ensure the safe and effective use of seamless pipes in chemical processing facilities, there are a few regulations that need to be followed:

1. Material selection

Select the appropriate seamless pipe material based on the nature of the chemical substances processed in the chemical treatment facility and the working conditions. Common materials include stainless steel, carbon steel, alloy steel, etc., which need to be selected according to specific circumstances.

2. Dimensions and pressure ratings

Select the appropriate seamless pipe size and pressure rating based on the operating pressure and flow requirements in the chemical processing facility. The size and pressure rating of the pipes need to meet the design requirements of the facility to ensure proper flow of fluids.

3. Installation and maintenance

The main uses of seamless pipe in chemical processing facilities include the following:

1. Transport chemical fluids

Seamless pipes can withstand extreme conditions such as high temperature and high pressure, so they are suitable for transporting various chemical fluids, such as acids, alkalis, solvents, etc. At the same time, because its inner wall is smooth, it is not easy for substances to adhere, ensuring the purity of the fluid.

2. Cooling and heating media

Seamless pipes are often used as conductive conduits for cooling and heating media in chemical processing facilities. Its high thermal conductivity and high temperature resistance allow it to effectively transfer heat and meet the facility's temperature control requirements.

3. Storing and transporting gases

Seamless pipe is also commonly used to store and transport gases in chemical processing facilities. It has the characteristics of good sealing and strong pressure resistance, which can ensure the safe storage and transportation of gas.

To ensure the safe and effective use of seamless pipes in chemical processing facilities, there are a few regulations that need to be followed:

1. Material selection

Select the appropriate seamless pipe material based on the nature of the chemical substances processed in the chemical treatment facility and the working conditions. Common materials include stainless steel, carbon steel, alloy steel, etc., which need to be selected according to specific circumstances.

2. Dimensions and pressure ratings

Select the appropriate seamless pipe size and pressure rating based on the operating pressure and flow requirements in the chemical processing facility. The size and pressure rating of the pipes need to meet the design requirements of the facility to ensure proper flow of fluids.

3. Installation and maintenance

The installation and maintenance of seamless pipes need to be carried out in strict accordance with relevant regulations. During installation, the correct connection and sealing of the pipelines must be ensured. During maintenance, the integrity and operating status of the pipelines must be regularly checked, and repairs and replacements must be made in a timely manner.

Go here to learn more about " How to Choose a Suitable Seamless Steel Pipe Material?"

©2017 Permanent Steel Manufacturing Co.,Ltd https://www.permanentsteel.com All Rights Reserved.

Terms of Sale|Privacy Policy