How to Shape Stainless Steel Elbows and How to Maintain them?

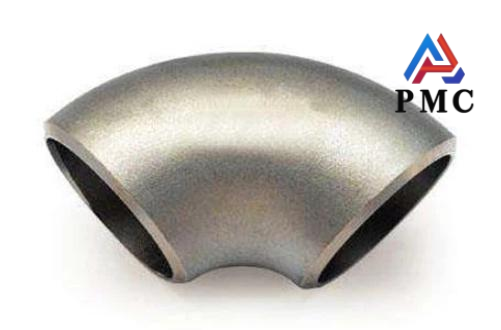

Stainless steel elbows are pipe connectors made of stainless steel, used to change the direction of the pipe. They are divided into 90°, 45°, 180° and other specifications according to the angle. Common materials include 304, 316, etc.

Its core advantage is strong corrosion resistance, can resist acid and alkali solutions and humid environment erosion, smooth surface and not easy to scale, which meets the standards of clean fields such as food and medical. In terms of technology, it is formed by pushing, pressing or welding, with high strength and good pressure resistance, and can withstand the transportation needs of high-temperature steam and corrosive media.

It is widely used in chemical, petroleum, pharmaceutical, building water supply and drainage and other scenes. It can not only ensure the sealing of the pipeline system, but also extend the service life. It is a key component with both practicality and durability in industrial pipeline connection.

Forming process of stainless steel elbow

The main materials of stainless steel elbows and carbon steel elbows are different. The chemical composition of stainless steel itself can prevent the surface of the elbow from corrosion for a long time, but this does not mean that stainless steel elbows do not need repair. The following will introduce how to form stainless steel elbows and how to maintain them.

1. Cold bending uses different bending test devices to push and bend the tube billet in an ordinary hydraulic press or crank press. The stainless steel straight tube billet is pressed into the mold at room temperature to form a stainless steel elbow. The bending radius of stainless steel elbows suitable for cold push bending becomes smaller, and the minimum bending radius is relatively r≤d≤1. The cross-section ovality of the bent pipe is small (≤3%≤5%), the outer pipe wall gradually becomes thinner (≤9%), and the structure is simple. No special equipment is required, and the production efficiency is high, but the design of stainless steel elbows of different thicknesses requires t≥0.06. Otherwise, due to poor rigidity, the steel billet tends to lose stability, resulting in wrinkling or deformation of the elbow.

2. Under the action of special axial thrust, the hot push rod pushes the bending deformation of the tube at the axial center to expand in the circumferential and axial directions, and the small diameter tube is pushed into the large diameter elbow.

Maintenance of stainless steel elbows

1. Stainless steel elbows that are stored for a long time need to be checked regularly. If they are exposed to the outdoors for a long time, they should be kept clean and free of dirt. They should be stored in a dry and ventilated clean room and should not be stacked or stored in the open air. Because stainless steel elbows should be kept dry and breathable, they should be stored with precise storage methods.

2. During installation, the stainless steel elbow device can be directly installed according to the location of use. When installing the stainless steel elbow, attention should be paid to sealing to prevent large amounts of leakage from affecting the normal operation of the pipeline. It is generally installed anywhere in the pipeline, and attention should be paid to easy operation.

3. Stainless steel elbow stop valves, ball valves and gate valves can only be fully opened or closed when in use, and the flow rate cannot be adjusted to avoid corrosion of the sealing surface and accelerate wear of the sealing surface.

4. Install the handwheel on the stainless steel elbow without using levers or other tools to avoid damage to valve parts. The handwheel rotates clockwise and counterclockwise.

5. The valve sealing working pressure cover bolts of the stainless steel elbow should be tightened smoothly and should not be pressed into a tilted and expanded state, otherwise we may encounter or hinder the movement of the valve stem, causing leakage. When using stainless steel elbows, they must be kept clean. If no problems are found, stop as soon as possible.

Read more: Common Standards for Stainless Steel Elbows