Differences between ASTM A53 and ASTM A500

Pipes are an integral part of the construction industry. Pipelines not only carry water, gas and oil to where they are needed in factories, but they also carry waste. But the question is, between ASTM A53 and ASTM A500 steel pipes, which one should you choose?

ASTM A53 and ASTM A500 specification steel pipe have similar functions. However, there are some significant differences that you must be aware of before making your final purchasing decision.

The ASTM A53 standard defines steel pipes intended for use in high-pressure gas or water transportation systems. It is one of the most important standards for industry standards related to steel. The ASTM A53 specification covers seamless and welded steel pipes, line pipes for oil and gas pipelines, and partially-processed tubing. It’s also ideal for electric resistance-welded subassemblies or pipeline joints.

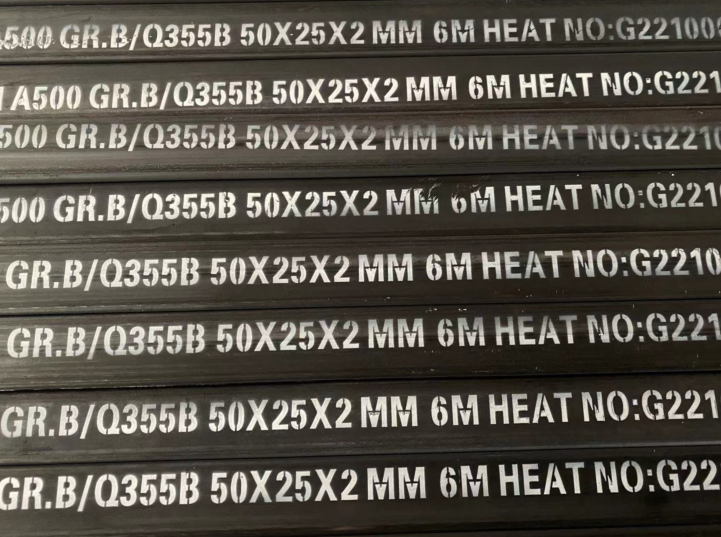

The ASTM A500 specification covers black carbon steel mechanical tubing. It’s primarily used in industrial plant construction. It also includes a galvanized coating applied before shipment from factory stock.

Although these pipes are made of steel, there are many differences between them. ASTM A53 steel pipe is thicker and stronger than A500 steel pipe. They can be used in high-pressure applications, and ASTM A500 steel pipe is suitable for pressures up to one hundred pounds per square inch. When choosing which pipe to use, consider the maximum expected pressure and the environmental conditions the pipe is likely to encounter.

What is the difference between in quality and strength?

ASTM A510 has a minimum yield strength of 60,000 PSI, while ASTM A53 has a minimum yield strength of 45,000 PSI. You'll notice that both materials have similar tensile properties around 100,000 PSI.

ASTM A53 steel pipe is more flexible than A510, but it is important to remember that A53 has a lower yield strength.

Characteristics and applications of ASTM A500 steel pipe:

ASTM A500 steel pipe is used for structural purposes such as heavy equipment and piping in the petrochemical and refining industries. However, the ASTM A53 is more common than the A500. Compared to ASTM A500 Grade B, A510 provides a better balance between strength and weldability.

Characteristics and applications of ASTM A53 steel pipe:

ASTM A53 Grade C steel pipe is used for mechanical purposes. However, its strength properties make it ideal for heavy equipment and pipelines in the petroleum industry.

Chemical composition:

1. The chemical composition of steel pipes affects the mechanical properties of the pipe, such as tensile and yield strength. The chemical composition of ASTM A500 steel pipe is equal to 0.28% C, 0.07% Mn, 0.07% Si, and 0.6-0.8% Ni.

2. The chemical composition of ASTM A53 steel pipe is typically equal to 0.22% C, 0.09% Mn, 0.09% Si, and 0.6-0.8% Ni. The ASTM A500 tolerances are more potent than the A53 pipe tolerances. They’re used in applications that need to be solid and durable against corrosion-related problems like seawater or sulphuric acid.

3. The chemical composition of the ASTM A500 steel pipe also allows it to be used in more applications than the A53 steel pipe. It has higher tensile strength, yielding strength, and corrosion resistance than the A53 steel pipe does. For these reasons, ASTM A500 steel pipes are usually more expensive than ASTM A53 steel pipes.

Tips: ASTM A53 Grade B is more popular than other grades. These pipes can be bare pipes without any coating, or it may be Hot-Dipped or Zinc-Coated and manufactured by Welding or by a Seamless manufacturing process. In Oil and Gas, A53 grade erw pipes are used in the structural and non-critical applications.