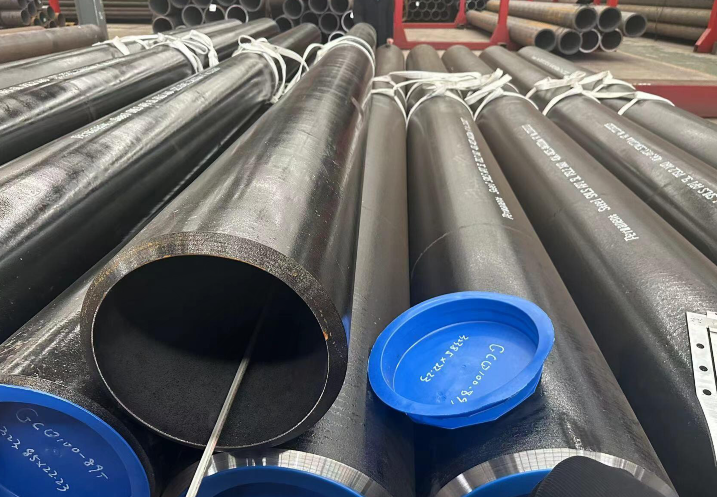

API 5L X60 Pipe, Grade X60 Seamless Line Pipe

API 5L X60 Pipe, Grade X60 Line Pipe, X60 Carbon Steel Seamless Line Pipe, X60 PSL1/ PSL2 Carbon Steel Pipe Supplier

X60 Seamless line pipe is a high-strength, medium-carbon steel pipe whose chemical composition and mechanical properties are precisely controlled and adjusted to meet specific requirements. The "X" represents pipeline steel, and the number 60 represents its minimum yield strength of 60,000 psi. This means that X60 steel pipe has good strength and toughness when withstanding pressure and load. X60 line pipe is used for oxygen, water and oil transportation pipes in the petroleum and natural gas industries.

Mechanical properties of X60 steel pipe:

Non-proportional extension strength RP0.2 (MPa): 415~565

Tensile strength (MPa): ≥520

Elongation A (%): ≥ 18

X60 Chemical analysis:

C: ≤ 0.21

Si: ≤ 0.45

Mn: ≤ 1.60

P: ≤0.020

S: ≤0.010

V: ≤ 0.15

Nb: ≤ 0.05

Ti: ≤0.04

X60 steel pipe production process:

The production of X60 steel pipes is mainly carried out through the seamless steel pipe production process. First, high-quality steel billets will be selected, and after pretreatment, they will be perforated by a piercing machine; then, the perforated steel billet will be stretched, wall thickness reduced and other processes through the rolling mill, and finally the X60 carbon seamless steel pipe will be obtained.

Application fields of X60 steel pipe:

X60 steel pipes are widely used in oil and natural gas transmission pipeline systems. Its high strength and corrosion resistance make it ideal for long-distance pipelines, capable of withstanding high pressures and long distances.

X60 steel pipes also have important applications in the chemical industry. Due to its good corrosion resistance, X60 steel pipe can be used to transport various chemical substances, including acid, alkali and salt solutions.

The high strength and toughness of X60 steel pipe make it suitable for various structural projects, such as bridges, buildings and offshore platforms. It can withstand complex mechanical loads and maintain structural stability and safety.

X60 line pipe heat treatment and hardness testing:

The surface heat treatment of X60 line pipe is divided into two categories, one is chemical heat treatment, and the other is surface quenching and tempering heat treatment. The hardness testing method is as follows:

1. Chemical heat treatment of X60 line pipe

Chemical heat treatment is to penetrate the atoms of one or several chemical elements into the surface of X60 pipeline pipe, thereby changing the chemical composition, structure and performance of the surface of X60 pipeline pipe. After quenching and low-temperature tempering, the surface of X60 line pipe has high hardness, wear resistance and contact fatigue strength, while the core of X60 line pipe has high strength and toughness.

The main technical parameters of chemical heat treatment X60 line pipe are the depth of hardened layer and surface hardness. The depth of the hardened layer still needs to be tested with a Vickers hardness tester. Detect the distance from the surface of the X60 line pipe to the point where the hardness drops to 50HRC. This is that the surface hardness testing of the effective hardening depth chemical heat treatment X60 pipeline pipe is similar to the hardness testing of the surface quenching heat treatment The thicker one is thinner, generally no more than 0.7mm. In this case, the Rockwell hardness tester can no longer be used, and a microhardness tester can be used.

2. X60 line pipe surface quenching and tempering heat treatment

Surface quenching and tempering heat treatment is usually carried out by induction heating or flame heating. The main technical parameters are surface hardness, local hardness and effective hardened layer depth. Hardness testing can be done with a Vickers hardness tester, a Rockwell or a surface Rockwell hardness tester. The selection of the test force (scale) is related to the depth of the effective hardened layer and the surface hardness of the X60 line pipe. There are three types of hardness testers involved.

The Vickers hardness tester is an important means of testing the surface hardness of heat-treated Small differences in tube surface hardness. In addition, the depth of the effective hardened layer must also be detected by a Vickers hardness tester. Therefore, it is necessary to equip a Vickers hardness tester for units that perform surface heat treatment processing or use a large number of surface heat treatment workpieces.

The surface Rockwell hardness tester is also very suitable for testing the hardness of surface quenched X60 pipeline pipe. The surface Rockwell hardness tester has three scales to choose from. Various surface-hardened X60 line pipes with effective hardening depth exceeding 0.1mm can be tested. Although the surface Rockwell hardness tester is not as accurate as the Vickers hardness tester, it can already meet the requirements as a testing method for quality management and qualification inspection in heat treatment plants. Moreover, it also has the characteristics of simple operation, convenient use, low price, rapid measurement, and the ability to directly read the hardness value. The surface Rockwell hardness tester can be used to quickly and non-destructively inspect batches of surface heat-treated X60 pipeline pipes one by one. This is of great significance to X60 line pipe processing and machinery manufacturing plants.

When the surface heat treatment hardened layer is thick, the Rockwell hardness tester can also be used. When the thickness of the heat treatment hardened layer is between 0.4 and 0.8mm, the HRA scale can be used. When the thickness of the hardened layer exceeds 0.8mm, the HRC scale can be used.

The three hardness values of Vickers, Rockwell and Superficial Rockwell can be easily converted to each other and converted into hardness values required by standards, drawings or users. The corresponding conversion tables are given in the international standard ISO, the American standard ASTM and the Chinese standard GB/T.

3. Local heat treatment

If the parts require high local hardness, local quenching heat treatment can be carried out by induction heating. Such X60 pipeline pipes usually need to mark the location of local quenching heat treatment and the local hardness value on the drawing. The hardness testing of X60 line pipe should be carried out in the designated area. The hardness testing instrument can use a Rockwell hardness tester to test the HRC hardness value. If the heat treatment hardened layer is shallow, a surface Rockwell hardness tester can be used to test the HRN hardness value.

Go here to learn more about " API 5L Line Pipe"