Epoxy Coating

-

Epoxy Coating

Steps:

Optimal internal pipe surface temperature is created prior to epoxy coating. Another air pressure leak test is performed. Conditioned air is then introduced into the pipe to evenly distribute the epoxy coating throughout the piping system. Following the coating application, conditioned and controlled air flows through the pipes to facilitate epoxy curing.

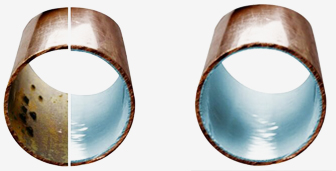

The end result is a smooth, permanent epoxy coating barrier between your pipes and water. After the epoxy coating cures new valves and hoses are installed to all fixtures. A final pressure test and flow test is performed to confirm system functionality.

Benfits

Safe and Durable

epoxy is certified safe to NSF/ANSI Standard 61 by Truesdail Laboratories.

Cost Effective

Epoxy Coating is as much as 50% less expensive than traditional pipe replacement costs.

Minimal Downtime / Disruption

The epoxy coating process takes a fraction of the time of traditional re-pipe methods.