Wall Thickness Deviation Range of Welded Steel Pipes

Overview:

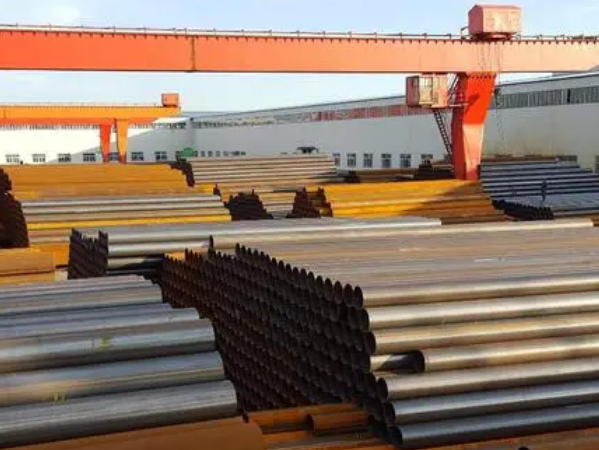

Welded steel pipe (such as ERW welded pipe) is a commonly used building material in modern construction, ships, machinery, bridges and other industries. During the production process, wall thickness deviations of steel pipes are inevitable, so a reasonable deviation range needs to be determined to ensure the safety and stability of welded steel pipes during use.

Standard positive and negative range of welded steel pipe thickness:

The thickness standard of welded steel pipes is usually expressed by the pipe wall thickness, which is generally divided into thin-walled pipes, standard pipes, thick-walled pipes and extra-thick-walled pipes. According to industry standards, the positive and negative range of the welded steel pipe thickness standard is about ±12.5% of the pipe wall thickness, which means a certain error is allowed. Specifically, for ordinary welded steel pipes:

1. Thin-walled pipe: The pipe wall thickness is within 3mm, and the allowable error is about ±0.3mm.

2. Standard pipe: The pipe wall thickness is between 3mm and 20mm, and the allowable error is about ±10% of the pipe wall thickness.

3. Thick-walled pipe: The pipe wall thickness is between 20mm and 40mm, and the allowable error is about ±12.5% of the pipe wall thickness.

4. Extra thick-walled pipe: The pipe wall thickness is above 40mm, and the allowable error is about ±12.5% of the pipe wall thickness.

It should be noted that the positive and negative ranges here are not fixed values and depend on the technical level and quality requirements of the steel pipe manufacturer. Therefore, when choosing welded steel pipes, it is recommended to choose regular manufacturers and reliable brands to ensure that product quality and technical standards are met.

Deviation range standards for welded steel pipes:

According to national standards, the wall thickness deviation range of welded steel pipes should be determined according to the following standards:

1. Conventional welded steel pipe: wall thickness deviation shall not exceed plus or minus 10%;

2. High-precision welded steel pipe: wall thickness deviation shall not exceed plus or minus 5%;

3. Ultra-high precision welded steel pipe: wall thickness deviation shall not exceed plus or minus 2%.

The above deviation range is determined with reference to national standards. In fact, the standards of each manufacturer may be slightly different, and the specific standards shall prevail.

Factors affecting the wall thickness deviation of welded steel pipes:

The main factors affecting the wall thickness deviation of welded steel pipes are as follows:

1. Uneven thickness of pipe wall;

2. Cooling process after welding;

3. Accuracy of raw materials;

4. The degree of curvature of the pipe wall.

Therefore, during the production process, attention needs to be paid to controlling these factors to ensure the quality of welded steel pipes.

Conclusion:

A reasonable deviation range can ensure the safety and stability of welded steel pipes during use. The deviation range stipulated in the standard is that the wall thickness of the welded steel pipe is about plus or minus 10%. The specific deviation range needs to be calculated in accordance with relevant standards. During the production process, attention needs to be paid to controlling factors such as the uneven thickness of the pipe wall, the cooling process after welding, the accuracy of the raw materials, the degree of curvature of the pipe wall, etc., to ensure the quality of the welded steel pipe.

Read more: Types and Uses of Welded Steel Pipes