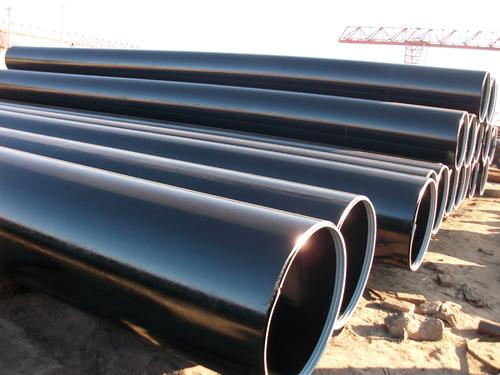

ERW Pipe Meaning

ERW Pipe Meaning:

ERW is the abbreviation of Electric Resistance Welding. The ERW pipe often referred to in the steel pipe industry refers to electric resistance welded pipe. The ERW welded pipe production line can produce high-frequency resistance longitudinal welded pipes, square pipes, rectangular pipes, steel sheet piles and other products.

Electric resistance welded steel pipes are divided into two types: AC welded steel pipe and DC welded steel pipe. AC welding is divided into low frequency welding, intermediate frequency welding, super intermediate frequency welding and high frequency welding according to the different frequency. High-frequency welding is mainly used for the production of thin-walled steel pipes or ordinary thick-walled steel pipes. High-frequency welding is divided into contact welding and induction welding. DC welding is generally used for small diameter steel pipes. Generally speaking, the high frequency welded pipe is included in the ERW welded pipe, which is a kind of ERW welded pipe produced by the high frequency welding process. ERW longitudinal welded pipe is a steel pipe with advanced performance, leading quality and relatively economical product in the field of oil and gas storage and transportation.

Electric resistance welding is a kind of pressure welding, in which the edge of the weld is heated to the welding temperature and pressure welds the welded pipe of the composite pipe. It is divided into low frequency and high frequency. Unlike ordinary welded pipe welding process, the weld is formed by melting the base material of the steel strip body, and its mechanical strength is better than that of ordinary welded pipe. The welding methods of erw pipes and submerged arc welded pipes are significantly different. The pressure welding method without filler metal is adopted. There are no other components filled in the weld. The skin effect and proximity effect of the high-frequency current make the edge of the plate instantaneously heated. When the welding temperature is reached, the welding seam of the forging structure is formed by the extrusion roller. High-quality steel pipes require on-line or off-line heat treatment of welds to refine the weld zone structure. The welds of high-quality erw welded pipes can reach the same toughness level as the base metal, which cannot be achieved by submerged arc welding.

ERW stands for resistance welding. Resistance welding has the characteristics of high production efficiency, low cost, material saving, and easy automation. Therefore, it is widely used in aviation, aerospace, energy, electronics, automobiles, light industry and other industrial sectors as one of the important welding processes. It is commonly used to transport oil, natural gas and other vapor and liquid objects, and can meet various requirements of high and low pressure. It currently plays a pivotal role in the field of transportation pipes in the world.

Tips: ASTM A53 Grade B is the grade in ERW high frequency welded pipe ( a53b erw), divided into A and B grades. ASTM is only a set of specifications. ASTM steel pipe A53 A corresponds to the Chinese standard GB8163 raw material is 10# steel, and A53 B corresponds to the Chinese standard GB8163 raw material 20#.

For example: ASTM (standard) A53 (grade) gr (abbreviation of grade) b (grade B)