Causes and Preventive Measures of OCTG Casing Damage

Date:2024-03-29 keywords: octg casing damage, casing pipe damage, casing repair, oil well casing damage

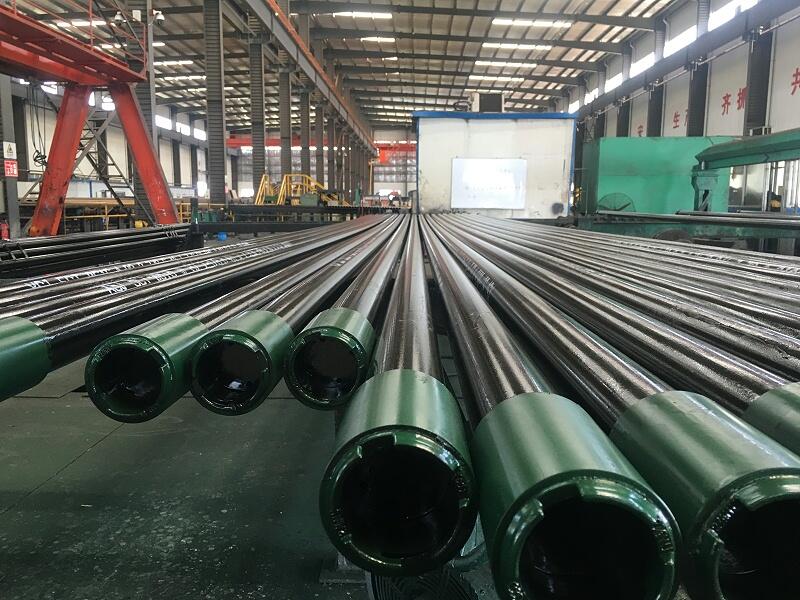

OCTG casing is an important part of an oil well, responsible for carrying the weight of surface drilling rigs, transporting oil and gas through pipelines, and maintaining wellbore stability. However, due to various reasons such as crustal activity, chemical effects, and mechanical factors, oil casings are easily damaged and even lead to production accidents. This article will discuss the causes of OCTG casing damage and propose corresponding preventive measures.

1. Corrosion

Oil well casing is exposed to the underground environment for a long time and is subject to a variety of chemical corrosion, especially in the presence of sulfur-containing compounds, oxides or acidic substances. Corrosion can cause the casing wall to become thinner and even form holes, leading to accidents such as oil and gas leakage and wellhead collapse. To prevent corrosion, the following methods can be used:

●Use anti-corrosion materials to make casings.

●Spray anti-corrosion coating on the inner wall of the casing.

2. Wear and tear

During the drilling process of oil well casing, mechanical effects such as seismic movement and drill bit rotation will cause wear on the casing surface. Wear will cause the casing wall to become thinner or even worn through, causing accidents such as oil and gas leakage or well wall collapse. To prevent wear and tear, you can use the following methods:

●Improve the hardness and strength of casing material.

●Use appropriate lubricants to reduce wear.

●Control the rotation speed and working pressure of the drill bit.

3. Pressure

During the production process, oil well casing will withstand high-pressure impacts, such as oil and gas explosions, earthquakes, etc., which will cause deformation and rupture of the casing and well wall, causing oil and gas leakage, well wall collapse and other accidents. To prevent damage caused by pressure, use the following methods:

●Choose casing materials with high strength and good toughness.

●Reinforce the well wall structure and improve the stability of the well.

●Install a pressure valve to control wellhead pressure.

4. Temperature

During the production and drilling process, oil well casing will be affected by high temperatures, such as combustion of oil and gas, heating of drilling fluid, etc. High temperature will reduce the strength and toughness of the casing, causing accidents such as deformation and fracture of the casing. To prevent damage caused by temperature, use the following methods:

●Choose materials that still have good mechanical properties at high temperatures.

●Control the combustion temperature of oil and gas.

●Enhance cooling and heat dissipation measures.

5. Natural disasters

Oil wells are often affected by natural disasters such as earthquakes, storms, and floods. These disasters can cause serious damage to casings and well walls, and even lead to irreversible consequences such as wellhead collapse and oil and gas leakage. To reduce the impact of natural disasters on oil wells, the following measures can be taken:

●The site selection and design of oil wells must comply with geological characteristics and meteorological conditions.

●Establish a disaster early warning mechanism and take prevention, relocation and other measures in advance.

●Improve the defense capability of wellhead construction.

Conclusion:

Oil well casing damage is a major hidden danger to production safety in the petroleum industry. During the drilling and production process, the comprehensive impact of multiple factors must be fully considered and effective measures must be taken for prevention and control. We can choose appropriate materials, control operating parameters, and improve risk prevention capabilities to protect the safe operation of oil wells.

1. Corrosion

Oil well casing is exposed to the underground environment for a long time and is subject to a variety of chemical corrosion, especially in the presence of sulfur-containing compounds, oxides or acidic substances. Corrosion can cause the casing wall to become thinner and even form holes, leading to accidents such as oil and gas leakage and wellhead collapse. To prevent corrosion, the following methods can be used:

●Use anti-corrosion materials to make casings.

●Spray anti-corrosion coating on the inner wall of the casing.

●Inject preservatives for protection.

2. Wear and tear

During the drilling process of oil well casing, mechanical effects such as seismic movement and drill bit rotation will cause wear on the casing surface. Wear will cause the casing wall to become thinner or even worn through, causing accidents such as oil and gas leakage or well wall collapse. To prevent wear and tear, you can use the following methods:

●Improve the hardness and strength of casing material.

●Use appropriate lubricants to reduce wear.

●Control the rotation speed and working pressure of the drill bit.

3. Pressure

During the production process, oil well casing will withstand high-pressure impacts, such as oil and gas explosions, earthquakes, etc., which will cause deformation and rupture of the casing and well wall, causing oil and gas leakage, well wall collapse and other accidents. To prevent damage caused by pressure, use the following methods:

●Choose casing materials with high strength and good toughness.

●Reinforce the well wall structure and improve the stability of the well.

●Install a pressure valve to control wellhead pressure.

4. Temperature

During the production and drilling process, oil well casing will be affected by high temperatures, such as combustion of oil and gas, heating of drilling fluid, etc. High temperature will reduce the strength and toughness of the casing, causing accidents such as deformation and fracture of the casing. To prevent damage caused by temperature, use the following methods:

●Choose materials that still have good mechanical properties at high temperatures.

●Control the combustion temperature of oil and gas.

●Enhance cooling and heat dissipation measures.

5. Natural disasters

Oil wells are often affected by natural disasters such as earthquakes, storms, and floods. These disasters can cause serious damage to casings and well walls, and even lead to irreversible consequences such as wellhead collapse and oil and gas leakage. To reduce the impact of natural disasters on oil wells, the following measures can be taken:

●The site selection and design of oil wells must comply with geological characteristics and meteorological conditions.

●Establish a disaster early warning mechanism and take prevention, relocation and other measures in advance.

●Improve the defense capability of wellhead construction.

Conclusion:

Oil well casing damage is a major hidden danger to production safety in the petroleum industry. During the drilling and production process, the comprehensive impact of multiple factors must be fully considered and effective measures must be taken for prevention and control. We can choose appropriate materials, control operating parameters, and improve risk prevention capabilities to protect the safe operation of oil wells.

Read more: What are the Grades of OCTG Casing Material?

- 【Prev】 : Precautions when Drilling Casing

- 【Next】 : Causes and Types of Oil Well Casing Damage

©2017 Permanent Steel Manufacturing Co.,Ltd https://www.permanentsteel.com All Rights Reserved.

Terms of Sale|Privacy Policy