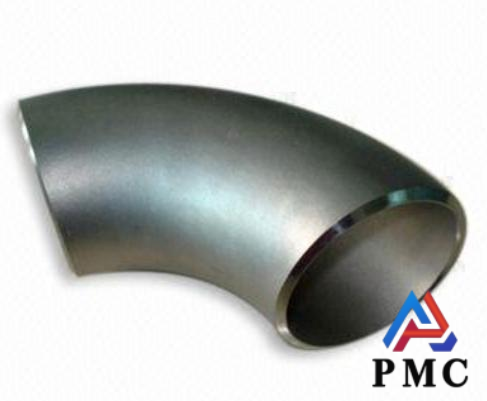

Application of Stainless Steel Elbows in Marine Engineering

In marine engineering, the pipeline system is the key channel for transporting various media such as oil, gas, and seawater. However, ordinary pipelines are prone to corrosion, deformation, and even rupture in such harsh environments. For example, some traditional pipes cannot resist the erosion of seawater. After a period of use, the pipe wall will become thinner, resulting in a significant increase in the risk of leakage. In addition, under the extreme conditions of high pressure and low temperature in the deep sea, some pipes will become fragile and their toughness will decrease, affecting their normal use. For this reason, the performance requirements for pipeline connection components have also risen, and stainless steel elbows have become an ideal choice in marine engineering pipeline systems due to their unique advantages.

Advantages of stainless steel elbows in marine engineering

1. Anti-corrosion Challenge: Guardian of the Marine Environment

Salt spray, seawater immersion and microbial activities in the marine environment pose a serious corrosion threat to metal materials. Stainless steel elbows, especially those containing molybdenum 316 or higher grades, can effectively resist pitting and crevice corrosion caused by chloride ions, protect the pipeline system from erosion, extend service life, and reduce maintenance costs. They are the preferred materials for marine engineering to resist harsh environments.

2. Strength and toughness: coping with deep-sea pressure

The high-pressure environment in the deep sea poses a great challenge to the pipeline system. Stainless steel elbows not only have high strength and can withstand huge underwater pressure, but also have good toughness to ensure that they are not easy to break under high temperature and high pressure fluctuations, ensuring the safety and stability of deep-sea oil and gas extraction, submarine cable laying and other operations.

3. Rapid guarantee of fluid transmission

The fluid transmission system in marine engineering requires fast and stable transmission. Stainless steel elbows effectively reduce fluid resistance and eddy currents through accurate fluid mechanics design, such as optimized curvature radius and smooth inner wall, which improves fluid transmission efficiency and reduces energy consumption. This is especially important for long-distance submarine pipeline transmission, ensuring uninterrupted transmission of energy and communication signals.

4. Convenience of installation and maintenance

The marine engineering operation environment is complex and the maintenance cost is high. The stainless steel elbow is easy to weld and has strong plasticity, which simplifies the on-site installation process and reduces the difficulty and time of construction. Its good maintainability makes it easy to inspect and replace even when repairing on offshore platforms or underwater, ensuring the continuous operation of the system.

5. Environmental friendliness and sustainable development

While pursuing economic benefits, marine engineering also pays more and more attention to environmental protection. The durability and recyclability of stainless steel elbows meet the requirements of green development, reduce the frequent replacement of materials and the generation of waste, and play a positive role in protecting the ocean.

Specific application of stainless steel elbows in marine engineering

1. Subsea pipeline system

In deep-sea oil and gas exploitation, the submarine pipeline is the key channel for transporting oil and gas from the submarine wellhead to the land or offshore platform. Stainless steel elbows are widely used in the turns and branches of the pipeline to ensure smooth and stable transportation of oil and gas.

2. Offshore oil drilling platform

The pipeline system on the platform is complex, including crude oil transportation, seawater injection, sewage treatment and other links. Stainless steel elbows are used to connect pipelines of different directions to meet the connection needs of various equipment on the platform. Its high strength and corrosion resistance can withstand the vibration, impact and harsh marine environment during platform operation, ensuring the normal production and operation of the platform.

3. Desalination plant

During the desalination process, seawater needs to go through a series of treatment processes. Stainless steel elbows are used in pipeline systems in various links such as seawater intake, pretreatment, and reverse osmosis. In the case of frequent contact with high-salinity seawater, its good corrosion resistance effectively prevents corrosion damage to the pipeline, ensuring that the desalination plant can continuously and stably produce fresh water and provide reliable fresh water resources for islands, coastal cities, etc.

Read more: Precautions for Installation and Maintenance of Stainless Steel Elbows