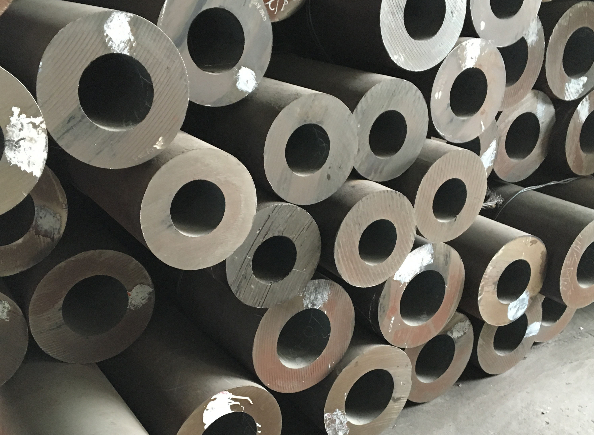

Analysis of High Temperature Temper Brittleness of Thick-walled Seamless Steel Pipe

Date:2021-07-08 keywords:thick-walled seamless steel pipe

Thick-walled seamless steel pipe has the characteristics of high strength, good hardenability, good toughness, small quenching deformation, high temperature creep strength and high endurance strength. Used to manufacture forgings with higher strength and larger quenched and tempered section than 35CrMo thick-walled seamless steel pipes, such as large gears for locomotive traction, supercharger transmission gears, pressure vessel gears, rear axles, connecting rods, spring clamps, etc. It has a large load and can be used for drill pipe joints, fishing tools and bending machine molds in deep wells below 2000 meters.

After the precision bright tube is quenched to obtain the martensite structure, it is tempered in the temperature range of 450-600℃; or after tempering at 650℃, it passes through 350-600℃ at a slow cooling rate; or after tempering at 650℃, 16Mn seamless steel pipe Long-term heating in the temperature range of 350 to 650°C will cause embrittlement of the precision bright tube. If the embrittled precision steel pipe is reheated to 650℃ and then cooled quickly, the toughness can be restored, so it is also called reversible temper brittleness; high temperature temper brittleness is manifested by the increase of the "toughness-brittleness" transition temperature of the precision bright tube. Sensitivity is generally expressed by the difference between the "toughness-to-brittle" transition temperature between the toughened state and the brittle state.

The effects of elements in thick-walled seamless steel pipes on high temperature temper brittleness are divided into:

(1) Impurity elements such as phosphorus, tin, antimony, etc. that cause high temperature tempering brittleness of precision bright tubes.

(2) Alloy elements that promote or slow down the brittleness of high temperature tempering in different forms and degrees. Chromium, manganese, nickel, silicon, etc. play a promoting role, while molybdenum, tungsten, titanium, etc. play a retarding role. Carbon also plays a catalytic role. Generally, carbon precision bright tube is not brittle to high temperature tempering. Sensitive, binary or multi-element alloys containing chromium, manganese, nickel, and silicon.

Thick-walled seamless steel pipe(astm a106) is a nickel-iron-chromium heat-resistant alloy, which has better high-temperature strength by adding a certain amount of silicon element. Because thick-walled seamless steel pipes have high high temperature strength, excellent high temperature oxidation resistance and medium corrosion resistance, they are more and more widely used in the aerospace + petrochemical and chemical metallurgical industries. Because the coal dry distillation process uses high-temperature coal gas to perform low-temperature pyrolysis of low-rank coal, the coal gas is heated by a gas heating furnace and enters the dry distillation section of the furnace body to pyrolyze the coal. The coal gas contains water vapor, a small amount of H2S and other corrosive gases. Therefore, it is required that the material of the heating furnace has better high temperature corrosion resistance.

News Update :

Should Steam Pipelines Use Seamless or Welded Pipes?...

©2017 Permanent Steel Manufacturing Co.,Ltd https://www.permanentsteel.com All Rights Reserved.

Terms of Sale|Privacy Policy