Advantages and Disadvantages of Seamless Carbon Steel Pipes

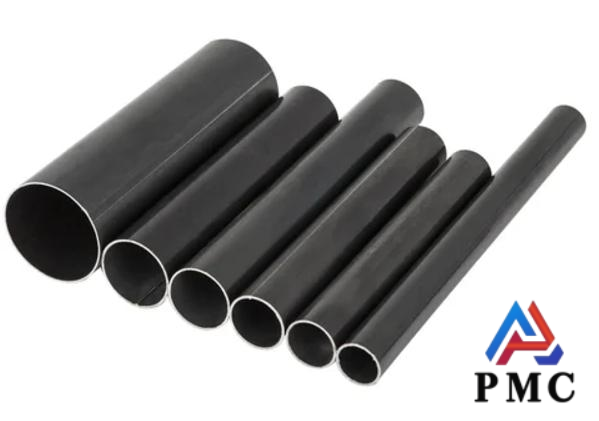

Seamless carbon steel pipe is made of steel ingot or solid tube by perforation into rough tube, and then hot rolled, cold rolled or cold drawn. Seamless carbon steel pipe plays an important role in my country's steel pipe industry. The following are the advantages, disadvantages and common materials of seamless carbon steel pipes

Advantages of Seamless Carbon Steel Pipes

1. High strength: Seamless carbon steel pipes have high strength and hardness, can withstand greater pressure and weight, and are suitable for high-pressure, high-temperature, and high-strength working environments, such as oil and natural gas pipelines, transmission shafts in machinery manufacturing, etc.

2. Good processing performance: easy to cut, weld, bend and other processing operations, can be made into pipes of various shapes and sizes according to different engineering requirements, the manufacturing process is relatively simple, the production cost is low, and it can meet the needs of large-scale production.

3. Economical and affordable: Compared with seamless tubes made of stainless steel, alloy steel and other materials, seamless carbon steel pipes are relatively cheap and have a higher cost-effectiveness. In some occasions where corrosion resistance is not required, the use of seamless carbon steel pipes can effectively reduce engineering costs.

4. Good thermal conductivity: Carbon steel has a high thermal conductivity, which makes it advantageous in some applications that require good thermal conductivity, such as pipes in heat exchangers, boilers and other equipment, which can effectively transfer heat and improve energy efficiency.

Disadvantages of Seamless Carbon Steel Pipes

1. Poor corrosion resistance: Carbon steel is easily oxidized in the air. In a humid environment or in a medium containing corrosive media, such as acid, alkali, and salt solutions, it is easy to corrode and rust, thus affecting the service life and safety of the pipeline. Corresponding anti-corrosion measures need to be taken, such as painting, galvanizing, and lining with anti-corrosion materials.

2. Poor low-temperature toughness: The toughness of seamless carbon steel pipes will be significantly reduced in low-temperature environments, becoming brittle and hard, and prone to brittle fracture. Therefore, when used under low-temperature conditions, it is necessary to choose carbon steel materials with good low-temperature toughness, and Take appropriate insulation measures.

3. Limited heat resistance: Generally, the strength and stability of seamless carbon steel pipes will decrease in high temperature environments. When the temperature exceeds a certain range, its performance may not meet the requirements, and deformation, oxidation and other problems may occur. For high temperature application scenarios, it may be necessary to choose heat-resistant alloy steel and other more heat-resistant materials.

4. High maintenance cost: Since seamless carbon steel pipes are prone to corrosion and rust, they need to be inspected, maintained and treated with anti-corrosion regularly, which increases the maintenance cost and workload during use. If the maintenance is not done properly, it may cause pipeline leakage, damage and other problems, affecting normal production and use.

Common seamless carbon steel pipes materials

1. 10# steel: low carbon content, good toughness and ductility, excellent welding performance, easy to process and shape, often used to manufacture pipes that do not require high strength but need good plasticity and weldability, such as some common fluid delivery pipes, water supply and drainage pipes in building structures, etc.

2. 20# steel: It has slightly higher strength than 10# steel, better toughness and welding performance, and has certain corrosion resistance and can withstand certain pressure. It is widely used in general fluid delivery pipelines and some parts manufacturing in mechanical structures, such as bicycle frames, automobile transmission shafts, etc.

3. 45# steel: It is a medium carbon steel with high strength. After proper heat treatment, it can obtain good comprehensive mechanical properties, such as strength, toughness and wear resistance. It is often used to manufacture mechanical parts, such as the load-bearing parts of automobiles and tractors, such as gears and shaft parts. It can also be used to manufacture some pipelines that have certain requirements for strength and wear resistance.

4. Q345B: It is a low-alloy high-strength structural steel. On the basis of carbon steel, a small amount of alloying elements, such as manganese and silicon, are added to significantly improve the strength and toughness. It has good comprehensive mechanical properties and welding performance. It can be used to manufacture structural parts and pipelines that can withstand higher pressures and loads, such as bridges, girders in building structures, support structures for large mechanical equipment, and high-pressure fluid pipelines.

5. Q355B: Similar to Q345B, it is also a low-alloy high-strength structural steel. Its mechanical properties such as yield strength have been improved, and it has better load-bearing capacity and fatigue resistance. It is suitable for engineering structures and mechanical parts with high strength and safety requirements, such as key components in high-rise buildings, large bridges, heavy machinery, and high-pressure, high-strength transmission pipelines.

6. 16Mn: It is a widely used low alloy structural steel with good comprehensive mechanical properties, high strength, good toughness, excellent welding performance and cold forming performance. It can be used to manufacture various engineering structures and parts in mechanical products, such as pressure vessels, bridges, ships, vehicles, etc. It is also widely used in pipeline systems in the petroleum, chemical, electric power and other industries.