Measures to Avoid Warping at the End of Steel Pipe 3PE Anti-corrosion Layer

It is analyzed that when the 3PE anti-corrosion layer steel pipe is grinding the groove of the polyethylene layer of the reserved section, the weld height of the pipe end is not ground or the ground is uneven, which will cause the epoxy powder at the bottom of the polyethylene bottom of the welding seam to be abraded. When the anti-corrosion pipe is stacked in the open air for a long time, the surface metal of the weld will be corroded first, which will cause the phenomenon of warping of the 3PE anti-corrosion layer.

The measures to avoid warping at the end of the 3PE anti-corrosion layer are:

1. Under the condition of not affecting the welding of the nozzle, the reserved length of the epoxy powder at the end of the polyethylene layer should be appropriately increased to prevent the 3PE anti-corrosion warping caused by the long stacking time of the steel pipe and the serious metal corrosion of the pipe end.

2. When anti-corrosion pipes are stacked in the open air for a long time, they should be covered at the pipe ends to prevent rainwater from corroding and causing serious corrosion of the pipe ends.

3. If the pipeline construction period is long, weldable anti-rust paint can be painted on the bare metal of the pipe end to prevent the 3PE anti-corrosion layer from warping due to corrosion during storage.

4. Strictly control the grinding quality of the welding seam reserved at the pipe end. The outside of the polyethylene groove at the weld is the same as other parts of the pipe body. Keep the epoxy powder longer than 20mm to prevent the bottom of the epoxy powder at the weld from being corroded first and causing the 3PE anti-corrosion layer to warp. Attention should be paid to the grinding of pipe end welds:

1) From the beginning of the weld grinding to the polyethylene chamfer, there should be a flat section of the polyethylene layer of 10-20mm with no excess weld height and the same polyethylene layer as the pipe body to ensure the extrusion and bonding of the polyethylene groove at the pipe end quality.

2) The reinforcement after grinding of the weld seam should be as level as possible with the pipe body, and there should be no obvious reinforcement, so as to prevent the epoxy powder from being polished away when grinding the chamfer of the polyethylene layer.

3) The chamfer of the undressed top of the weld and the transition section of the repaired place should also be the same as the chamfer of the polyethylene layer (≤30°), so that the squeezing force of the squeeze roller is evenly applied to the polyethylene layer To prevent the polyethylene layer from curling due to poor adhesion of the anti-corrosion layer at the groove.

5. The epoxy powder coating of the reserved section can only delay the edge warping caused by corrosion of the pipe end only if the protection is complete. Domestic pipe end polyethylene bevel processing is all polished with steel wire wheels, which will damage the epoxy powder coating. The groove should be machined instead, and the bottom layer of the knife edge should be limited by a device to control the cutting depth of the tool, so as not to damage the epoxy powder coating.

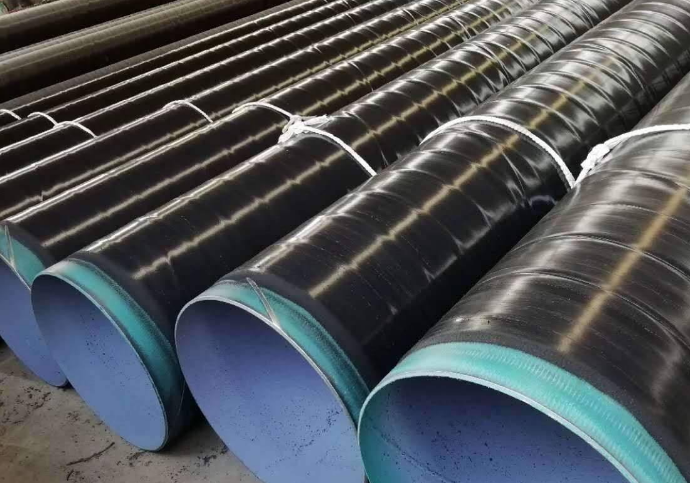

Tips: 3PE anticorrosive spiral steel pipe(ssaw) anticorrosive structure: the first layer of epoxy powder (FBE>100um), the second layer of adhesive (AD) 170~250um, the third layer of polyethylene (PE) 1.8~3.7mm. The three materials are integrated and firmly combined with the steel pipe to form an excellent anti-corrosion layer. The pipe diameter ranges from Φ60 to Φ1420.

2PE anticorrosive pipeline Two-layer PE anticorrosive structure: the first layer of adhesive (AD), the second layer of polyethylene (PE), the two materials are integrated, and the thickness of each layer is the same as that of the three layers of PE.