Carbon Steel vs. Stainless Steel: What's the Difference?

Date:2021-12-10 keywords: carbon steel vs stainless steel, carbon steel pipe vs stainless steel pipe

Carbon Steel

Mainly refers to the steel whose mechanical properties depend on the carbon content in the steel, and generally do not add a large amount of alloying elements. Sometimes it is also called plain carbon steel or carbon steel, which refers to iron-carbon alloys with a carbon content of less than 2% WC.

In addition to carbon, carbon steel generally contains a small amount of silicon, manganese, sulfur, and phosphorus. The higher the carbon content of carbon steel, the greater the hardness and the higher the strength, but the lower the plasticity.

Classification of Carbon Steel:

1. Carbon steel can be divided into three types: carbon structural steel, carbon tool steel and free-cutting structural steel according to its purpose. Carbon structural steel is further divided into two types: architectural structural steel and machine-manufactured structural steel;

2. According to the smelting method, it can be divided into open hearth steel, converter steel and electric furnace steel;

3. According to the deoxidation method, it can be divided into boiling steel (F), killed steel (Z), semi-killed steel (b) and special killed steel (TZ);

4. Carbon steel can be divided into low carbon steel (WC ≤ 0.25%), medium carbon steel (WC 0.25%-0.6%) and high carbon steel (WC>0.6%) according to the carbon content;

Stainless Steel

Stainless acid-resistant steel is referred to as stainless steel. It is composed of two parts: stainless steel and acid-resistant steel. In short, steel that can resist atmospheric corrosion is called stainless steel, and steel that can resist chemical media corrosion is called acid-resistant steel. Rusty steel is a high-alloy steel with more than 60% iron as the matrix and adding alloying elements such as chromium, nickel, and molybdenum.

When the chromium content in the steel exceeds 12%, the steel is not easy to corrode and rust in the air and dilute nitric acid. The reason is that chromium can form a very tight chromium oxide film on the steel surface, which effectively protects the steel from corrosion. The chromium content in stainless steel generally exceeds 14%, but stainless steel is not absolutely rust-free. In coastal areas or some places with serious air pollution, when the chlorine ion content in the air is high, the stainless steel surface exposed to the atmosphere may have some rust spots, but these rust spots are limited to the surface and will not erode the internal matrix of the stainless steel.

Generally speaking, steel with a content of WCr greater than 12% has the characteristics of stainless steel. According to the microstructure after heat treatment, stainless steel can be divided into five categories: ferritic stainless steel, martensitic stainless steel, and austenitic stainless steel. , Austenitic-ferritic stainless steel and precipitation carbide stainless steel.

Stainless steel is usually divided into:

1. Ferritic stainless steel. Containing 12% to 30% chromium. Its corrosion resistance, toughness and weldability increase with the increase of chromium content, and its resistance to chloride stress corrosion is better than other types of stainless steel.

2. Austenitic stainless steel. The chromium content is more than 18%, and it also contains about 8% nickel and a small amount of molybdenum, titanium, nitrogen and other elements. Good overall performance, resistant to corrosion by various media.

3. Austenitic-ferritic duplex stainless steel. It has the advantages of austenitic and ferritic stainless steel, and has superplasticity.

4. Martensitic stainless steel. High strength, but poor plasticity and weldability.

Carbon Steel vs. Stainless Steel: What's the Difference?

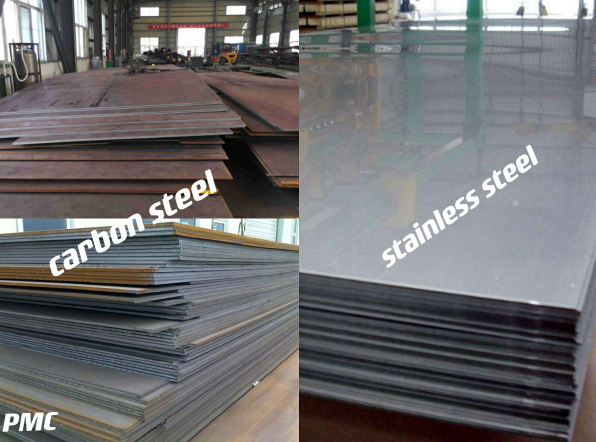

1. Different colors: stainless steel contains more chromium and nickel metals, and the exterior color is mostly bright silver. Carbon steel is mainly carbon and iron alloy, and other metal elements are relatively small. The main color of the outer surface is the color of iron, and the color will be much darker.

2. Different textures: stainless steel contains many other metal elements and has a smooth surface, while carbon steel contains iron and carbon and has the essence of iron, but the surface is not as smooth as stainless steel.

3. Different magnetism: the surface of carbon steel is magnetized and can be attracted by magnets. Stainless steel has no magnetism under normal conditions and will not be attracted by magnets.

4. Different carbon elements: Carbon steel mainly refers to the steel whose mechanical properties depend on the carbon content of steel, and generally do not add a large amount of alloy metal elements, in which the carbon content WC is less than 2%. In order to maintain corrosion resistance, stainless steel contains carbon content. Both are low, and the maximum does not exceed 1.2%.

5. Different alloy content: Carbon steel contains few alloying elements, only a small amount of silicon, manganese, sulfur, and phosphorus. Stainless steel contains a lot of gold elements, and the main chromium and nickel elements exceed 12%.

Mainly refers to the steel whose mechanical properties depend on the carbon content in the steel, and generally do not add a large amount of alloying elements. Sometimes it is also called plain carbon steel or carbon steel, which refers to iron-carbon alloys with a carbon content of less than 2% WC.

In addition to carbon, carbon steel generally contains a small amount of silicon, manganese, sulfur, and phosphorus. The higher the carbon content of carbon steel, the greater the hardness and the higher the strength, but the lower the plasticity.

Classification of Carbon Steel:

1. Carbon steel can be divided into three types: carbon structural steel, carbon tool steel and free-cutting structural steel according to its purpose. Carbon structural steel is further divided into two types: architectural structural steel and machine-manufactured structural steel;

2. According to the smelting method, it can be divided into open hearth steel, converter steel and electric furnace steel;

3. According to the deoxidation method, it can be divided into boiling steel (F), killed steel (Z), semi-killed steel (b) and special killed steel (TZ);

4. Carbon steel can be divided into low carbon steel (WC ≤ 0.25%), medium carbon steel (WC 0.25%-0.6%) and high carbon steel (WC>0.6%) according to the carbon content;

5. According to phosphorus and sulfur content, carbon steel can be divided into ordinary carbon steel (higher phosphorus and sulfur), high-quality carbon steel (lower phosphorus and sulfur) and high-quality high-quality steel (lower phosphorus and sulfur) ) And super high-quality steel.

Stainless Steel

Stainless acid-resistant steel is referred to as stainless steel. It is composed of two parts: stainless steel and acid-resistant steel. In short, steel that can resist atmospheric corrosion is called stainless steel, and steel that can resist chemical media corrosion is called acid-resistant steel. Rusty steel is a high-alloy steel with more than 60% iron as the matrix and adding alloying elements such as chromium, nickel, and molybdenum.

When the chromium content in the steel exceeds 12%, the steel is not easy to corrode and rust in the air and dilute nitric acid. The reason is that chromium can form a very tight chromium oxide film on the steel surface, which effectively protects the steel from corrosion. The chromium content in stainless steel generally exceeds 14%, but stainless steel is not absolutely rust-free. In coastal areas or some places with serious air pollution, when the chlorine ion content in the air is high, the stainless steel surface exposed to the atmosphere may have some rust spots, but these rust spots are limited to the surface and will not erode the internal matrix of the stainless steel.

Generally speaking, steel with a content of WCr greater than 12% has the characteristics of stainless steel. According to the microstructure after heat treatment, stainless steel can be divided into five categories: ferritic stainless steel, martensitic stainless steel, and austenitic stainless steel. , Austenitic-ferritic stainless steel and precipitation carbide stainless steel.

Stainless steel is usually divided into:

1. Ferritic stainless steel. Containing 12% to 30% chromium. Its corrosion resistance, toughness and weldability increase with the increase of chromium content, and its resistance to chloride stress corrosion is better than other types of stainless steel.

2. Austenitic stainless steel. The chromium content is more than 18%, and it also contains about 8% nickel and a small amount of molybdenum, titanium, nitrogen and other elements. Good overall performance, resistant to corrosion by various media.

3. Austenitic-ferritic duplex stainless steel. It has the advantages of austenitic and ferritic stainless steel, and has superplasticity.

4. Martensitic stainless steel. High strength, but poor plasticity and weldability.

Carbon Steel vs. Stainless Steel: What's the Difference?

1. Different colors: stainless steel contains more chromium and nickel metals, and the exterior color is mostly bright silver. Carbon steel is mainly carbon and iron alloy, and other metal elements are relatively small. The main color of the outer surface is the color of iron, and the color will be much darker.

2. Different textures: stainless steel contains many other metal elements and has a smooth surface, while carbon steel contains iron and carbon and has the essence of iron, but the surface is not as smooth as stainless steel.

3. Different magnetism: the surface of carbon steel is magnetized and can be attracted by magnets. Stainless steel has no magnetism under normal conditions and will not be attracted by magnets.

4. Different carbon elements: Carbon steel mainly refers to the steel whose mechanical properties depend on the carbon content of steel, and generally do not add a large amount of alloy metal elements, in which the carbon content WC is less than 2%. In order to maintain corrosion resistance, stainless steel contains carbon content. Both are low, and the maximum does not exceed 1.2%.

5. Different alloy content: Carbon steel contains few alloying elements, only a small amount of silicon, manganese, sulfur, and phosphorus. Stainless steel contains a lot of gold elements, and the main chromium and nickel elements exceed 12%.

6. Different corrosion resistance: carbon steel contains less alloying elements and has weak corrosion resistance, while stainless steel contains more chromium-nickel metal, which has strong corrosion resistance.

Read more: Carbon Steel Pipe VS. Stainless Steel Pipe

©2017 Permanent Steel Manufacturing Co.,Ltd https://www.permanentsteel.com All Rights Reserved.

Terms of Sale|Privacy Policy