316 Stainless Steel Pipe Purchasing Precautions

316 stainless steel pipe is a commonly used austenitic stainless steel pipe. Due to the addition of 2% molybdenum, its corrosion resistance is significantly improved compared to 304 stainless steel, especially in terms of resistance to chloride corrosion, high temperature resistance, acid and alkali resistance. It is suitable for high-demand scenarios such as marine engineering, food processing, chemical and pharmaceutical industries. The pipe has good toughness and welding performance, can be formed by cold working, is non-toxic and harmless, and meets hygiene standards. Its implementation standards include national standard GB/T 14976, American standard ASTM A312, etc., with various specifications, and are widely used in various fluid transportation and structural support fields.

Clear requirements specifications

1. Different usage scenarios have very different performance requirements for 316 stainless steel pipes. For example, chemical companies need pipes with stronger corrosion resistance when transporting highly corrosive media. Stainless steel pipes used in building structures focus more on their strength and stability.

2. The choice of pipe diameter, wall thickness and length is also critical. The pipe diameter needs to be determined according to the fluid flow and pressure. The wall thickness is related to the pressure-bearing capacity and service life of the pipeline. In high-pressure environments or working conditions with high corrosion resistance requirements, the wall thickness needs to be increased to ensure safety and durability. The standard length is generally 6 meters, but some suppliers also provide customized length services, so when purchasing, you must combine the actual installation conditions and usage requirements to accurately determine the required length to avoid waste or insufficient length.

3. The connection method cannot be ignored. Common ones include clamping type, ring pressing type, socket welding type, groove type, etc. Different connection methods are suitable for different pipe diameter ranges and application scenarios. For example, the compression connection is easy to operate and has good sealing performance. It is often used for the installation of small and medium diameter water pipes. Groove connection is suitable for large diameter pipes and is easy to install and maintain. Therefore, it is necessary to select the appropriate connection method according to the actual project conditions and construction requirements.

Focus on material quality

1. Checking the material certificate is the most basic operation. Regular 316 stainless steel pipe manufacturers will provide material certificates, which record in detail the chemical composition, mechanical properties and other key information of the pipe. Just like a person’s ID card, it can prove whether the "identity" of the pipe is qualified.

2. Testing the chemical composition is also an important means of distinguishing the quality of pipes. In addition to checking the chemical composition data in the material certificate, if conditions permit, you can also use professional testing instruments, such as spectrometers, to test the chemical composition of pipes and accurately determine the actual content of various elements to ensure compliance with standard requirements.

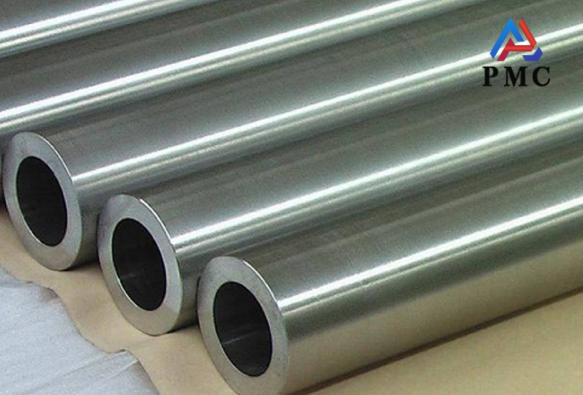

3. Appearance can also reveal a lot of information about the quality of the pipe. The surface of high-quality 316 stainless steel pipe should be smooth, flat, uniform in color, and free of obvious cracks, sand holes, pores and other defects.

Choose a regular supplier

1. Choosing a regular supplier is the key to purchasing high-quality 316 stainless steel pipes. First of all, examining the supplier's qualifications and reputation is the basis. At the same time, to understand the supplier's industry reputation and credibility, you can obtain information by checking online reviews, consulting other buyers, etc.

2. The supplier's production equipment and production capacity should not be ignored. Advanced production equipment is the hardware foundation to ensure product quality. Only with high-precision pipe making equipment and advanced testing instruments can we produce 316 stainless steel pipes that meet the standards.

3. Perfect after-sales service is also an important consideration. High-quality suppliers will provide comprehensive after-sales services, such as being responsible for product quality issues during the warranty period, responding to customers' after-sales needs in a timely manner, and providing technical support and solutions.

Focus on price and cost performance

From the material perspective, the higher the proportion of key alloy elements such as nickel and molybdenum, the higher the cost and naturally the higher the price.

Specifications are also key factors affecting price. Stainless steel pipes with large diameters and thick walls use more raw materials, which increases the difficulty and cost of processing, and therefore their prices are higher.

Market supply and demand also have an important impact on prices. When market demand is high and supply is relatively low, prices tend to rise; Conversely, when Supply exceeds demand, prices are likely to fall.

Read more: 316 Stainless Steel Pipe Inner Wall Coating Treatment