Standard Length of Carbon Steel Pipe

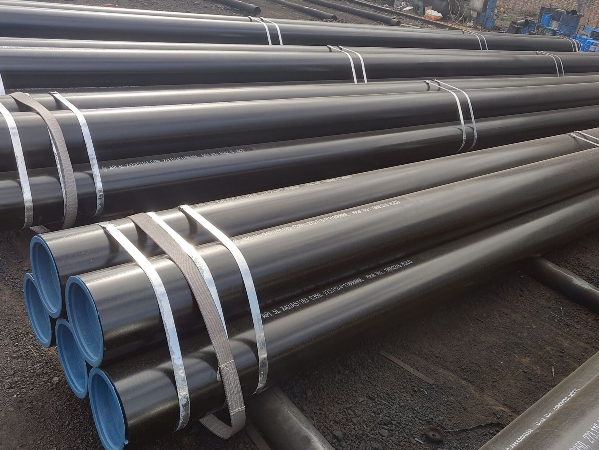

Seamless carbon steel pipe is a common pipeline material widely used in petroleum, chemical industry, electric power and other fields. Its size and specification standards are an important factor in ensuring the installation and use of pipelines.

The size specifications of seamless carbon steel pipes usually include outer diameter, wall thickness, length and other parameters. According to different application fields and requirements, the size specifications of seamless carbon steel pipes also vary. The following are several common sizes of seamless carbon steel pipes:

1. Seamless carbon steel pipes with a diameter of DN15-DN300mm have a wall thickness of 2.5-12mm and a length of generally 3-12m;

2. Seamless carbon steel pipes with a diameter of DN350-DN1000mm, a wall thickness of 6-25mm, and a length of usually 6-12m;

3. Seamless carbon steel pipes with a diameter of DN1200-DN2000mm, a wall thickness of 10-30mm, and a length of generally 8-12m.

However, according to the search results, in general, the standard lengths of carbon steel seamless pipes may be 5.8m, 6m, 11.8m, and can be customized according to customers' specific needs. If not specified, the length of seamless pipe is usually in the range of 6 to 10 meters, but other lengths are also possible, which may result in an increase in the material purchase price.

The size and specification standards of seamless carbon steel pipes mainly include the following aspects:

1. Outer diameter size standards: The outer diameter size of seamless carbon steel pipes should comply with the corresponding national standards or industry standards, such as GB/T 8163-2008, etc. Different models of seamless carbon steel pipes have different outer diameters, but they are usually designed in series to facilitate selection and production.

2. Wall thickness dimension standards: The wall thickness dimensions of seamless carbon steel pipes should comply with corresponding national standards or industry standards, such as GB/T 8163-2008, etc. On the premise of meeting the usage requirements, a thinner wall thickness should be chosen as much as possible to reduce cost and weight.

3. Length dimension standards: The length dimensions of seamless carbon steel pipes should comply with corresponding national standards or industry standards, such as GB/T 8163-2008, etc. Generally speaking, the length of seamless carbon steel pipes is between 6-12m, and can be customized under special circumstances.

4. Internal and external surface quality standards: The internal and external surfaces of seamless carbon steel pipes should be smooth, flat, and free of defects such as cracks, folds, and slag inclusions. For use occasions with special requirements, such as high temperature, high pressure, corrosion and other environments, corresponding internal and external surface treatment processes should be adopted to improve corrosion resistance and service life.

5. Mechanical performance standards: The mechanical properties of seamless carbon steel pipes should comply with corresponding national standards or industry standards, such as GB/T 8163-2008, etc. The main mechanical property indicators include tensile strength, yield point, elongation, impact toughness, etc. These indicators need to be selected and adjusted according to the specific application.

6. Corrosion resistance performance standards: Seamless carbon steel pipes used in corrosive environments should have good corrosion resistance. Appropriate anti-corrosion treatment processes, such as coating, lining, stainless steel coating, etc., should be selected according to the specific corrosive medium and usage conditions to ensure the service life and safety of the pipeline.

7. Quality assurance standards: The production and use of seamless carbon steel pipes should comply with corresponding quality assurance standards, such as ISO 9001, etc. During the production process, strict quality control and inspection should be carried out to ensure that each batch of seamless carbon steel pipes meets the corresponding quality standards. During use, regular inspection and maintenance should be carried out as needed to ensure the safety and stability of the pipeline.

Things to pay attention to when purchasing carbon steel pipes:

1. Select steel pipes of appropriate length according to usage requirements. Using shorter lengths of steel pipes can improve production efficiency and reduce costs, but the required strength and toughness need to be taken into consideration. Generally speaking, pipes with smaller diameters and shorter lengths are more versatile, while pipes with larger diameters and longer lengths are used to withstand greater loads and pressures.

2. Select steel pipes with appropriate specifications. The outer diameter and wall thickness of steel pipes are important indicators to consider when purchasing. Steel pipes with different outer diameters and wall thicknesses have different uses and need to be selected according to specific usage requirements.

3. Determine the material and surface treatment of the steel pipe. Carbon steel pipes are usually divided into several types: ordinary carbon steel pipes, low alloy high-strength steel pipes, alloy steel pipes, etc. In addition, the surface treatment method of steel pipes also needs to be selected according to the conditions of use, such as spray painting, anti-corrosion treatment, etc.

4. Check the quality of the steel pipe. When purchasing steel pipes, you need to check whether the appearance quality, dimensional deviation, chemical composition, mechanical properties and other indicators comply with national standards and contract requirements.

Conclusion:

When selecting the length of carbon steel pipes, steel pipes of appropriate length should be selected according to specific usage requirements, and attention should be paid to the strength, toughness and other characteristics that these steel pipes need to have. When purchasing, you also need to consider issues such as carbon steel pipe material, surface treatment method and quality requirements. Through reasonable purchase and use, the service life of steel pipes can be made more stable and safer.

- 【Prev】 : What is the Purpose of OCTG Casing Pipe?

- 【Next】 : What is OCTG Casing?