Sanitary Stainless Steel Tube - Permanent Steel Manufacturing Co.,Ltd

Date:2021-10-27 keywords:sanitary stainless steel tube, stainless steel sanitary tubing

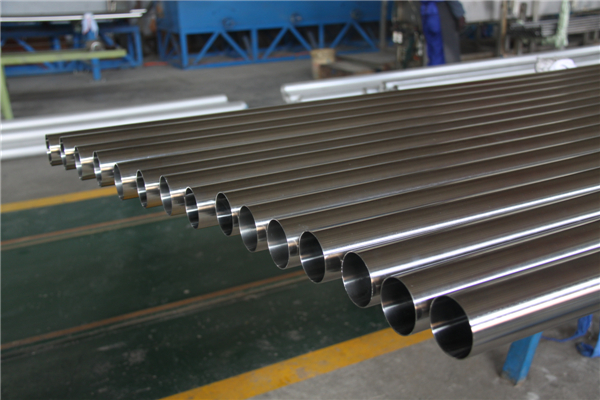

Sanitary stainless steel tubes (SS pipes) are also called seamless stainless steel pipes, which are made of steel ingots or solid tube billets through perforation and then made by hot rolling, cold rolling or cold drawing. Sanitary stainless steel pipes are mainly used in food, beverage, wine, biological engineering and other production equipment and assembly lines. The material is mainly 304 and 316 sanitary stainless steel pipes.

Sanitary stainless steel tubes have the characteristics of durability and almost no need to maintain the surface. It is precisely because this material is easy to form, durable and beautiful, so many architects choose stainless steel seamless pipes not only as a kind of protective layer, but also It is used as an integral part of the overall design.

Sanitary stainless steel tubes have a variety of different strength-to-weight ratios to meet the requirements of various building structures. In addition, different levels of surface finish also provide a range of options for various construction facilities to meet actual needs. Sanitary stainless steel tubes are polished, most of which are mechanically polished, and the general finish is between 0.3-1μm, which can basically meet the requirements of most people. The architect's bold ideas will make stainless steel seamless pipes increasingly widely used in the construction industry.

For steel pipes subjected to fluid pressure, hydraulic tests must be carried out to check their pressure resistance and quality, and no leakage, wetting or expansion under the specified pressure is qualified. Some steel pipes are also subject to crimping tests according to the standard or the buyer’s requirements. , Flaring test, flattening test.

Stainless steel product requirements: mainly for surface finish, oil forbidden and passivation layer.

1. Surface finish: Polish the inner and outer surfaces of the steel pipe to make the surface of the steel pipe a bright surface; that is, the mirror surface we often call. The main purpose is to prevent the fluid substance moving in the tube from forming a wall in the tube, which is easy to contaminate and cause blockage in the tube after a long time.

2. Passivation layer: After polishing, the steel pipe needs to be immersed in a passivation bath, and the surface of the steel pipe is oxidized with an acid passivation solution to form a passivation layer to achieve the anti-corrosion effect of the steel pipe.

3. Oil-free degree: After passivation is completed, oil-free cleaning is carried out to remove oil stains on the surface of the steel pipe. After completion, it needs to be inspected with a grease analyzer. It mainly prevents the oil pollution of the pipe wall itself from contaminating the fluid substances in the pipe.

Product features of sanitary stainless steel tube:

1) Better roundness:

Generally, the roundness of sanitary stainless steel pipes with an outer diameter below 38 is generally controlled below 1mm, and those with an outer diameter above 38 are controlled below 1.5mm. This is all for customers who have special requirements for products.

2) The appearance is bright, the inner hole is smooth:

The inner and outer surface finish Ra≤0.8μm, the inner and outer surface finish of the polished tube can reach Ra≤0.2-0.4μm (such as mirror surface), if the customer has the outer surface finish requirement, it can reach 0.1, or 8K surface.

3) Straightness range:

If the outer diameter is below 32, the straightness is less than 1mm/m, and if the outer diameter is more than 32, the straightness is less than 1.2mm/m. Generally finish rolling, if the whole tube is about 6m, the straightness is average.

Sanitary stainless steel tubes are used in the industry:

Used for pressure instrumentation: instrument packaging tube, conductive tube, power protection tube

Used in medical equipment: stainless steel tube medical tube, medical equipment tube

Used in food machinery: filling machine tube, baler tube, hydraulic packaging tube

Used in refrigeration machinery: cold press tube

Used in the automotive industry: automotive equipment pipe

©2017 Permanent Steel Manufacturing Co.,Ltd https://www.permanentsteel.com All Rights Reserved.

Terms of Sale|Privacy Policy