-

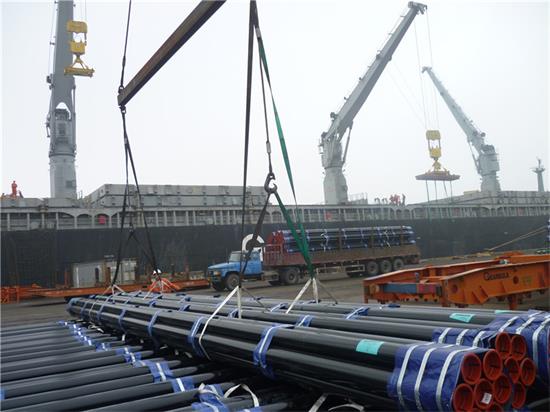

Tubo de carbono

+Tubería de perforación

Tubería de perforación

×+Tubo de Acero Sin Costura

+Tubería de Acero ERW

+Tubería de Acero SSAW

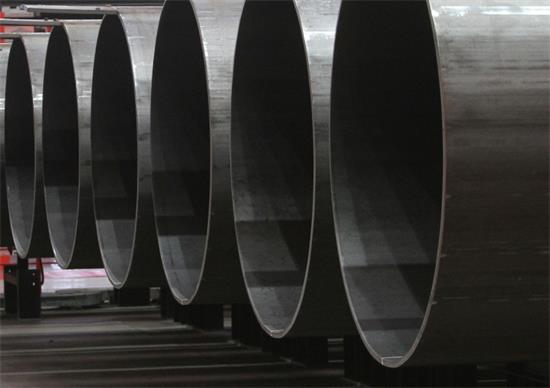

+Tubería de Acero LSAW

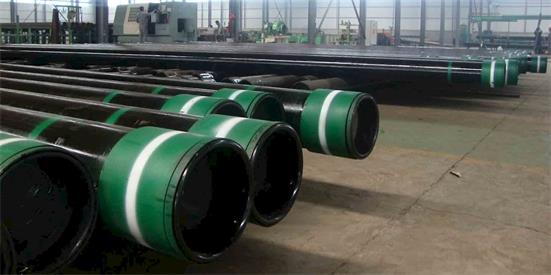

+Tubos & Carcasas

+Tubo de acero galvanizado

Tubo de acero galvanizado

1.Estándar: ASTM A53, BS1387-85, GB / T3091-08, DIN2440, JIS-G3444, EN10240, EN10255

2.Grado: Q195, Q215, Q235, Q345, S235JR, S275JR, STK400, STK500

3.Tipo y revestimiento de zinc:

Tubo de acero galvanizado en caliente (revestimiento de zinc: 60g / m2-275g / m2)

Tubo de acero galvanizado prepintado (revestimiento de zinc: 80g / m2-275g / m2)

4.Diámetro exterior:

Tubo redondo: 17 mm-273 mm

Tubo cuadrado: 15 mm x 15 mm - 400 mm x 400 mm

Tubo rectangular: 10 mm x 20 mm -200 mm x 400 mm

5. espesor de la pared:

Tubo redondo: 0.6mm-12mm

Tubo cuadrado: 0.6mm-20mm

Tubo rectangular: 0.6mm-20mm

6.Longitud: 2m-5.8m / 6m / 12m (podemos ajustar la longitud de acuerdo a su solicitud)

×

+Tubo de flexión

Inquiry Email:info@permanentsteel.com

Tubo de carbono

La tubería de acero al carbono fabricada por permanentsteel contiene tubería de acero sin costura, tubería de acero erw, tubería de acero de sierra, tubería de acero de sierra, carcasa de aceite y tubería de perforación, etc.

|

Tamaños de tubería sin costura |

Tamaños de tubería soldada |

Solicitud |

|

Fuera de diámetro: 1/4"-36" |

Out diameter: 21.3mm-3620mm |

API 5L, API 5CT,ASTM A53, ASTM A106, ASTM A179, ASTM A192, ASTM A252, ASTM A333, ASTM A335, ASTM A672

Agua subterránea |

|

Espesor de pared:1.25mm-50mm |

Wall thickness:1.65-mm-65mm |

|

|

Longitud:3m-12m |

Length:3m-12m |

| NPS | O.D | ANSI B36.10 B36.19 Wall Thickness | ||||||||||||||

| mm | in | mm | Sch5S | Sch10S | Sch10 | Sch20 | Sch30 | Sch40S | STD | Sch40 | Sch60 | Sch80 | XS | Sch80S | Sch100 | XXS |

| 8 | 1/4 | 13.72 | - | 1.65 | - | - | - | 1.73 | 1.73 | 1.73 | - | 3.02 | 3.02 | 3.02 | - | - |

| 10 | 3/8 | 17.14 | - | 1.65 | - | - | - | 2.31 | 2.31 | 2.31 | - | 3.2 | 3.2 | 3.2 | - | - |

| 15 | 1/2 | 21.34 | 1.65 | 2.11 | - | - | - | 2.77 | 2.77 | 2.77 | - | 3.73 | 3.73 | 3.73 | - | 7.47 |

| 20 | 3/4 | 26.67 | 1.65 | 2.11 | - | - | - | 2.87 | 2.87 | 2.87 | - | 3.91 | 3.91 | 3.91 | - | 7.82 |

| 25 | 1 | 33.4 | 1.65 | 2.77 | - | - | - | 3.38 | 3.38 | 3.38 | - | 4.55 | 4.55 | 4.55 | - | 9.09 |

| 32 | 1 1/4 | 42.16 | 1.65 | 2.77 | - | - | - | 3.56 | 3.56 | 3.56 | - | 4.85 | 4.85 | 4.85 | - | 9.7 |

| 40 | 1 1/2 | 48.26 | 1.65 | 2.77 | - | - | - | 3.68 | 3.68 | 3.68 | - | 5.08 | 5.08 | 5.08 | - | 10.16 |

| 50 | 2 | 60.32 | 1.65 | 2.77 | - | - | - | 3.91 | 3.91 | 3.91 | - | 5.54 | 5.54 | 5.54 | - | 11.07 |

| 65 | 2 1/2 | 73.02 | 2.11 | 3.05 | - | - | - | 5.16 | 5.16 | 5.16 | - | 7.01 | 7.01 | 7.01 | - | 14.02 |

| 80 | 3 | 88.9 | 2.11 | 3.05 | - | - | - | 5.49 | 5.49 | 5.49 | - | 7.62 | 7.62 | 7.62 | - | 15.24 |

| 90 | 31/2 | 101.6 | 2.11 | 3.05 | - | - | - | 5.74 | 5.74 | 5.74 | - | 8.08 | 8.08 | 8.08 | - | - |

| 100 | 4 | 114.3 | 2.11 | 3.05 | - | - | - | 6.02 | 6.02 | 6.02 | - | 8.56 | 8.56 | 8.56 | - | 17.12 |

| 125 | 5 | 141.3 | 2.77 | 3.4 | - | - | - | 6.55 | 6.55 | 6.55 | - | 9.53 | 9.53 | 9.53 | - | 19.05 |

| 150 | 6 | 168.28 | 2.77 | 3.4 | - | - | - | 7.11 | 7.11 | 7.11 | - | 10.97 | 10.97 | 10.97 | - | 21.94 |

| 200 | 8 | 219.08 | 2.77 | 3.4 | - | 6.35 | 7.04 | 8.18 | 8.18 | 8.18 | 10.31 | 12.7 | 12.7 | 12.7 | 15.09 | 22.22 |

| 250 | 10 | 273.05 | 3.4 | 3.76 | - | 6.35 | 7.8 | 9.27 | 9.27 | 9.27 | 12.7 | 12.7 | 12.7 | 15.09 | 18.26 | 25.4 |

| 300 | 12 | 323.85 | 3.96 | 4.57 | - | 6.35 | 8.38 | 9.52 | 9.52 | 10.3 | 14.27 | 12.7 | 12.7 | 17.48 | 21.44 | - |

| 350 | 14 | 355.6 | 3.96 | 4.78 | 6.35 | 7.92 | 9.52 | *9.52 | 9.52 | 11.13 | 15.09 | 12.7 | 12.7 | 19.05 | 23.83 | - |

| 400 | 16 | 406.4 | 4.19 | 4.78 | 6.35 | 7.92 | 9.52 | *9.52 | 9.52 | 12.7 | 16.66 | 12.7 | 12.7 | 21.44 | 26.19 | - |

| 450 | 18 | 457.2 | 4.19 | 4.78 | 6.35 | 7.92 | 11.12 | *9.52 | 9.52 | 14.27 | 19.05 | 12.7 | 12.7 | 23.82 | 29.36 | - |

| 500 | 20 | 508 | 4.78 | 5.54 | 6.35 | 7.92 | 12.7 | *9.52 | 9.52 | 15.09 | 20.62 | 12.7 | 12.7 | 26.19 | 32.54 | - |

| 550 | 22 | 558.8 | 4.78 | 5.54 | 6.35 | 7.92 | 12.7 | *9.52 | 9.52 | - | 22.22 | 12.7 | 12.7 | 28.58 | 34.92 | - |

| 600 | 24 | 609.6 | 5.54 | 6.35 | 6.35 | 7.92 | 14.27 | *9.52 | 9.52 | 17.48 | 24.61 | 12.7 | 12.7 | 30.96 | 38.89 | - |

| 650 | 26 | 660.4 | - | *7.92 | 7.92 | 12.7 | - | *9.52 | 9.52 | - | - | 12.7 | 12.7 | - | - | - |

| 700 | 28 | 711.2 | - | *7.92 | 7.92 | 12.7 | 15.88 | *9.52 | 9.52 | - | - | 12.7 | 12.7 | - | - | - |

| 750 | 30 | 762 | 6.35 | *7.92 | 7.92 | 12.7 | 15.88 | *9.52 | 9.52 | - | - | 12.7 | 12.7 | - | - | - |

| 800 | 32 | 812 | - | *7.92 | 7.92 | 12.7 | 15.88 | *9.52 | 9.52 | 17.48 | - | 12.7 | 12.7 | - | - | - |

| 850 | 34 | 863.6 | - | *7.92 | 7.92 | 12.7 | 15.88 | *9.52 | 9.52 | 17.48 | - | 12.7 | 12.7 | - | - | - |

| 900 | 36 | 914.4 | - | *7.92 | 7.92 | 12.7 | 15.88 | *9.52 | 9.52 | 19.05 | - | 12.7 | 12.7 | - | - | - |

| 950 | 38 | 965.2 | - | *7.92 | - | - | - | *9.52 | 9.52 | - | - | 12.7 | 12.7 | - | - | - |

| 1000 | 40 | 1016 | - | *7.92 | - | - | - | *9.52 | 9.52 | - | - | 12.7 | 12.7 | - | - | - |

| 1050 | 42 | 1066.8 | - | *7.92 | - | - | - | *9.52 | 9.52 | - | - | 12.7 | 12.7 | - | - | - |

| 1100 | 44 | 1117.6 | - | *7.92 | - | - | - | *9.52 | 9.52 | - | - | 12.7 | 12.7 | - | - | - |

| 1150 | 46 | 1168.4 | - | *7.92 | - | - | - | *9.52 | 9.52 | - | - | 12.7 | 12.7 | - | - | - |

| 1200 | 48 | 1219.2 | - | *7.92 | - | - | - | *9.52 | 9.52 | - | - | 12.7 | 12.7 | - | - | - |

| 1300 | 52 | 1320.8 | - | - | - | - | - | - | 9.52 | - | - | - | 12.7 | - | - | - |

| 1350 | 54 | 1371.6 | - | - | - | - | - | - | 9.52 | - | - | - | 12.7 | - | - | - |

| 1400 | 56 | 1422.4 | - | - | - | - | - | - | 9.52 | - | - | - | 12.7 | - | - | - |

| 1500 | 60 | 1524 | - | - | - | - | - | - | 9.52 | - | - | - | 12.7 | - | - | |

| 1600 | 64 | 1625.6 | - | - | - | - | - | - | 9.52 | - | - | - | 12.7 | - | - | |

| 1700 | 68 | 1727.2 | - | - | - | - | - | - | 9.52 | - | - | - | 12.7 | - | - | |

| 1800 | 72 | 1828.8 | - | - | - | - | - | - | 9.52 | - | - | - | 12.7 | - | - | |

| 1900 | 76 | 1930.4 | - | - | - | - | - | - | 9.52 | - | - | - | 12.7 | - | - | |

| 2000 | 80 | 2032 | - | - | - | - | - | - | 9.52 | - | - | - | 12.7 | - | - | |

Standard for carbon steel pipe

|

API 5L |

for use in conveying gas, water, and oil in the natural gas and oil industries, and covers seamless and welded steel line pipe. |

|

API 5CT |

for casing and tubing |

|

ASTM A53 |

for Pipe, Steel, Black and Hot-Dipped, Zinc-Coated, Welded and Seamless |

|

ASTM A106 |

for Seamless Carbon Steel Pipe for High-Temperature Service |

|

ASTM A179 |

for Seamless Cold-Drawn Low-Carbon Steel Heat-Exchanger and Condenser Tubes |

|

ASTM A192 |

for Seamless Carbon Steel Boiler Tubes for High-Pressure Service |

|

ASTM A213 |

for Seamless Ferritic and Austenitic Alloy-Steel Boiler, Superheater, and Heat-Exchanger Tubes |

|

ASTM A252 |

for Welded and Seamless Steel Pipe Piles |

| ASTM A333 |

for Seamless and Welded Steel Pipe for Low-Temperature Service and Other Applications with Required Notch Toughness |

|

ASTM A672 |

for Electric-Fusion-Welded Steel Pipe for High-Pressure Service at Moderate Temperatures |

|

ASTM A335 |

for Seamless Ferritic Alloy-Steel Pipe for High-Temperature Service |

|

DIN 17175 |

seamless steel pipes are used in boiler installations, high-pressure pipelines and tank construction and special machinery for both high temperature and high-pressure devices. |

|

DIN 1629 |

specifies the Seamless Circular Tubes of Non Alloys Steels with Special Quality Requirements. |

|

DIN 2391 |

for Cold Drawn High Precision Seamless Tube |

| DIN 2458 |

Welded Steel Pipes in Unalloyed and Low Alloy Steels for Supply Purposes |

|

EN 10210 |

Seamless steel tubes for pressure purposes |

|

BS 3059 |

Steel boiler and superheater tubes |

|

JIS G3454 |

Carbon steel pipes for pressure service |

Certificación de prueba de fábrica relevante para referencia, Haga clic aquí.